GRAITEC is supporting FORUM 8, its Value Added Reseller operating in Japan, by providing free Advance Steel and Advance Concrete licenses to the participants of FORUM 8’s 2nd Student BIM and VR Contest open to students worldwide.

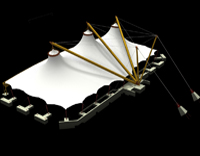

The theme of this year’s contest is “The Sustainable Design of a Marine City. The objective is to design a sustainable and self-sufficient Marine City on the sea with innovative designs to overcome the problems all modern cities face in the 21st century.

Work by each and every contestant will be uploaded on FORUM 8’s cloud server, VR-Cloud(R) server, to be judged on its logistics, technical and design aspect, as well as its creativity and how innovative it is. Participants are required to use FORUM 8’s award-winning software UC-win/Road, and at least one other software of their choice from a lineup of BIM and VR software available for free rental during the contest.

Advance Steel and Advance Concrete are among the software the participants can rely on to design and model innovative structure. For this purpose GRAITEC have conceded 50 free short term licenses of both Advance Steel licenses and Advance Concrete for the students. In July 17, Advance Steel and Advance Concrete experience seminars will be organized through 5 cities in Japan (Live-Tokyo TV Conference system- Osaka, Nagoya, Fukuoka. Sendai).

Advance Steel and Advance Concrete are among the software the participants can rely on to design and model innovative structure. For this purpose GRAITEC have conceded 50 free short term licenses of both Advance Steel licenses and Advance Concrete for the students. In July 17, Advance Steel and Advance Concrete experience seminars will be organized through 5 cities in Japan (Live-Tokyo TV Conference system- Osaka, Nagoya, Fukuoka. Sendai).

The Award for the winner is a grand prix worth approximately US$3,600 including scholarship, certificate, World cup Trophy and mementos. Among the rest of the participants, 5 lucky ones will also receive a laptop and every contestants will of course win a participation reward for their work. Applicants have until September 30th to register online. Once they have registered and created their VR model, they will need to submit their work including scripts during the period from October 1st to October 23rd, and once they have submitted their work, they will be notified of the webpage on FORUM 8’s VR-Cloud(R) server to which they can access to browse and test their submitted model, along with their login ID and password. FORUM 8 and special guest judges will come to a decision and determine the winners on November 20th, and they will be awarded in the awards ceremony the following day.

For more information, please contact:

Europe, The Middle East, Americas & Africa: office@forum8.com

Australia, New Zealand & Oceania: anita@forum8.co.jp

Asia and for all other general inquiries: yokoyama@forum8.co.jp

Check out last year’s winners: http://www.forum8.co.jp/english/studentBIM1-Award-e.htm

About FORUM 8

FORUM8, the Japanese 3D software specialist, produces state-of-the-art 3D VR and engineering software. Founded in 1987, FORUM8 is at the forefront of 3D Visual Interactive Simulation (3D VIS) technology and provides 3D VIS capabilities to specialists from various professions, including transportation, engineering, planning, emergency training, architecture, road safety and many more.

For more information, please visit www.forum8.com