This video shows how to quickly and accurately round trip fabrication information between Autodesk Advance Steel and Graitec Advance Workshop software. You will see:

– what information is exchanged between the two products

– how Advance Workshop utilizes this information in fabrication management

– how changes are synchronized and visualized using colorization of the 3D model in Advance Steel

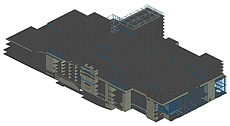

3D model

Steel-Glass façade for the most inclined Tower of the world

The façade of the Capital Gate in Abu Dhabi was constructed by Waagner-Biro Stahlbau AG with Advance Steel, the 3D-Software for steel constructions.

The façade of the Capital Gate in Abu Dhabi was constructed by Waagner-Biro Stahlbau AG with Advance Steel, the 3D-Software for steel constructions.

The spectacular skyscraper “Capital Gate” was created directly to the Abu Dhabi National Exhibition Center, the biggest area for trade shows and events in the Middle-East. The Capital Gate is 160m high and has an impressive inclination up to 18 degrees. Therefore it is more inclined than the leaning tower of Pisa that has only an inclination of 4 degrees. In the Guinness Book of Records the Capital Gate is already listed as the most leaning tower of the world. The building was erected between 2007 and 2010. It consists of 40 levels and is used as an office complex. In the 16th upper floors a five-star-Hyatt Hotel is located.

Waagner-Biro AG from Vienna was responsible for the modeling, construction, detailing and assembly of this extraordinary and organic formed steel-glass-facade of the Capital Gate. The tower has a polygonal foundation and the facade is one degree per level sloped and twisted. At the most inclined part the facade leans out more than 24m over the ground floor. The main-load bearing structure consists of a diamond structure.

More than 720 diamond elements were field-assembled by triangle sections with the glass and finally mount complete to the main structure. Each of those large-sized elements called “Diamonds” covers two levels and consists of 18 triangular areas and 33 single rods. For the entire facade 23.760 single bars and 12.960 glass panels were used. Because of the complex free formed surface each triangular glass panels and each single bar is unique. All in all more than 1.200 tons of steel and 24.000m2 glass was used for this extraordinary facade.

In order to realize the complex and challenging project in cost and on schedule, the 3D-CAD Software Advance Steel was used for planning. Thanks to its extensive 3D-tools it was easy to model the sculptured surface with nodes, rods and joints between them. Advance Steel processes the entire 3D model data, accelerates all document creation and insures all-around drawing consistency. An in-house programming on top of Advance Steel created all workshop documents (assembly drawings, GA-drawings, BOMs, NC-files) automatically from the 3D model.

Mr. Gert Weimann, head of engineering and construction department at Waagner-Biro AG, explains: “The project Capital Gate was a big challenge for us especially concerning the geometry, construction, detailing and assembly. Advance Steel increased the productivity in engineering and in the participated departments by more than 50% due to its 3D abilities and its possibilities of a comprehensive programming“.

About Waagner-Biro Stahlbau AG

Waagner-Biro is an international company for steel constructions and has its headquarters in Vienne, Austria. The company was founded in 1854. More than 1.000 employees work for Waagner-Biro in 16 offices in Europe, in South-East Asia and in the Arabic countries. Waagner-Biro is specialized in steel-glass-technology, bridge constructions, stage constructions and special mechanic engineering. Some of their main references are the cupola of the Reichstag in Berlin, the YAS-Marina Project in Abu Dhabi, the new airport terminal in Baku (Azerbaijan) and the Sony-Center in Berlin.

Video: Direct link between Advance Steel and BIM – Review from AceCAD

GRAITEC and AceCAD offer a direct link so that a 3D model done in Advance Steel can be successfully imported in BIMReview and then StruMIS.

This movie demonstrates how users may take advantage of this link by exporting the Advance Steel model to a *.gtcx file format and how this fully detailed model is imported and can be viewed & manipulated like any other BIMReview model.

As you can see with this movie, GRAITEC Advance Steel is fully BIM compliant allowing easy and seamless data sharing with BIMReview for easy project collaboration.

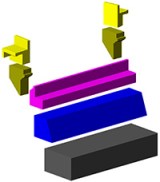

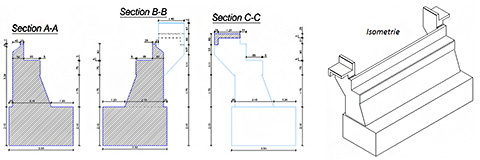

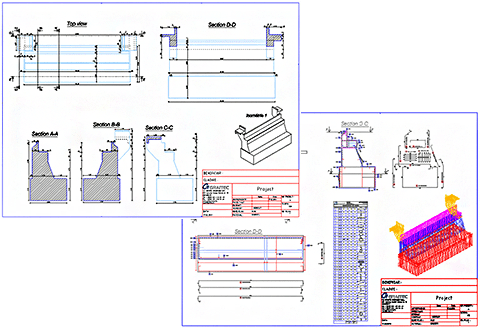

Reinforcement and formwork for complex shapes in Advance Concrete

The article describes how we can create reinforcement and formwork drawings for structures with a complex geometry, namely bridge abutment using Advance Concrete. The bridge abutment is a part of infrastructure which is created at the ends of the bridge in order to take the transmitted loads of the bridge superstructure and the supports of the access path to the bridge.

The article describes how we can create reinforcement and formwork drawings for structures with a complex geometry, namely bridge abutment using Advance Concrete. The bridge abutment is a part of infrastructure which is created at the ends of the bridge in order to take the transmitted loads of the bridge superstructure and the supports of the access path to the bridge.

To define the chosen geometry, an ACIS block can be created or the complex geometry can be divided into several blocks having a simple geometry which can be assembled in order to obtain the initial model.

We chose the second method for reasons related to the flexibility of Advance Concrete while modeling volume elements.

How to create any 3D concrete shape

Advance Concrete provides the creation of any 3D and 2D shapes. The predefined concrete shapes can be chosen from the library or new ones can be created. To add a new concrete shape it is enough to create a closed contour and then save the shape in the concrete library. These new shapes can then be used either in the current drawing or for other projects.

The created concrete elements are defined as beam and column structural elements. These are positioned one in regard to the other, composing the entire concrete ensemble.

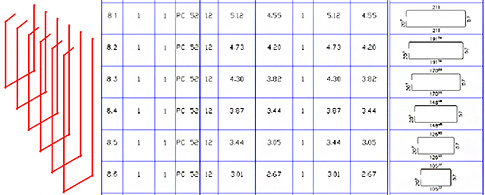

How to obtain a 3D reinforcement cage for special concrete shapes

The reinforcement drawing is created by selecting all the concrete elements. In the created reinforcement drawing, sections are added through the specific concrete zones.

The definition bars are created in one section and then distributed in elevation or top view. Several types of bars (straight, U and L bars) and distributions (linear, variable, multiple and quantitative) are available for use. The most frequent reinforcement bars are polygonal and straight bars and linear and variable distributions. Concrete covers can be set for each leg of the polygonal bar.

A reinforcement bar distributed in one view will automatically be available in all views, as long as the 3D power option is activated in the reinforcement drawing.

A reinforcement bar distributed in one view will automatically be available in all views, as long as the 3D power option is activated in the reinforcement drawing.

In order to obtain a correct reinforcement cage, the collisions between bars have to be avoided. The bar collisions can be visualized in 2D and 3D representations. They can be easily checked and corrected, at any point.

In order to obtain a correct reinforcement cage, the collisions between bars have to be avoided. The bar collisions can be visualized in 2D and 3D representations. They can be easily checked and corrected, at any point.

The bar detailing and reinforcement symbols can be done both manually (they can be customized and saved in the reinforcement symbol library) and automatically.

The bars numbering and lists creation is automatically done. Sub-entity marks are assigned for variable distributions, emphasizing that the variable distribution belongs to a single shape definition bar.

The drawings are created according to standard STAS 438/1,3 -89. The drawing creation according to other standards is similar.

Formwork details

The formwork drawing is created by adding the desired sections and elevations for structural elements, assigning specific hatches and line weights. The dimensioning of sections is quickly done by adding intersection and level dimensions.

Layout and Print

The reinforcement and formwork drawings can be placed in any page format. Also the views can be grouped and the title block can be attached according to the chosen format.

Numbering of the reinforcement bars and lists can be done in layout mode. The drawings can be printed one by one or by selecting several from the available print window.

Test it yourself

We have shown a simple example of a formwork and reinforcement cage created for a complex shape of the structural element. If you want to see the model described above, please download the specific model and drawings from here or, as a pdf file from here.

The example was created in Advance Concrete 2013.

Advance Steel Project: Manchester Road Bridge

Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

The steel structure of unique design was detailed in ADVANCE Steel by Briton Fabricators Lt. The building process started in November 2011 and over 10,000 components have been put together to compile the structure. It forms an elevated section of the Living Street and will be a gateway feature for Manchester Road. The bridge is close to a surface level signalized crossing which serves a bus stop on the guided bus route. All bridge ramps are 1:20 gradient, and the bridge 3.7 m in width. Access through the public park is 1:15 gradient.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

The fantastic new bridge links up local communities on either side of the bridge, providing a pleasant route for cyclists and pedestrians, and enabling quick and easy access to the town centre and other essential links, which were missing before. It also offers a more gentle approach to the old footbridge, which was nearly 40 years old and in need of serious maintenance to address time related deterioration. Manchester Road Bridge was built approximately in the same position as the old footbridge and was completed in September 2012. Hundreds of people turned out to see the bridge officially being opened. Although, during an average weekday, 621 people use the surface crossing of Manchester Road, and only 340 the footbridge, for reasons of safety the public authorities encourages everybody to use the new bridge to cross this busy junction.

Footbridge construction: Interview with LEGRAND

Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

In 1981, LEGRAND chose to diversify its client base and its business activities by creating a Steel Construction Department in the Quincieux site (Dpt 69). This department includes its own design office which is equipped with a modern and recently renewed IT infrastructure.

Currently, LEGRAND employs about 200 people.

Jean-Sébastien COURIVAUD, Design Office manager and Jean-Charles MASBOEUF, Draftsman, report their satisfaction of the Advance Steel software.

How did your drawing software equipment evolve within your Design Office?

J-S COURIVAUD: Ten years ago, we switched from the drawing board to the use of AutoCAD® in 2D, and then we realized the projects were becoming more and more complex. So we have equipped the Design Office with 3D CAD software dedicated to the steel construction industry in which 30 people are working at the Quincieux site. We initially started with Prosteel before choosing Advance Steel. After a personalized demonstration, it was clear that Advance Steel would provide us with significant productivity savings through the automatic detailing and the quality of the final drawings.

Today, we have 4 Advance Steel licenses to deal with our footbridge and highway bridge projects.

What are the advantages of Advance Steel compared to the software you were previously using?

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated AS document manager, which facilitates the overall project management.

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated AS document manager, which facilitates the overall project management.

J-C MASBOEUF: Our footbridges typically include curved elements such as lower arches supporting the steel structure and the bridge deck. Advance Steel knows how to manage these kinds of elements without affecting the global performances of the software.

How have you customized Advance Steel to match your work methods?

J-S COURIVAUD: Customized drawing styles have been created to produce drawings perfectly corresponding to our presentation criteria (dimension styles, line thickness, dimensions, etc.) and they can be directly launched from a dedicated toolbar that we have also created on our own.

J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments.

J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments.

With the help of the GRAITEC technical support, we configured Advance Steel to work with our fabrication machines at the workshop so that the unfolding of folded plates can be obtained by the criteria of the machines (value of the plate elongation, folding radius, plate thickness, etc.).

Can you give us a description of the footbridge project you recently built with Advance Steel?

J-C COURIVAUD: The construction is a pedestrians/cycles footbridge (access to Anonnay between Peaugres and Davézieux on the RD820). This steel footbridge with 40.30m straight span consists of a mixed steel/wood frame and a concrete floor on HEA 200 beams spaced every 3.40m.

The supporting structure is made up of 2 tapered glue-laminated arches 48cm apart and braced with steel parts. The latter are associated to the level of the deck with 2 lateral steel beams of constant height and connected vertically by two transverse V shaped steel stays (welded plates steel profile stays). The total weight of the structure is 32 tons.

How did you collaborate with the other companies working on this project?

J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

To conclude, what is your general impression of Advance Steel?

J-S COURIVAUD: Advance Steel allowed us to definitively move on to 3D design which gave us new opportunities and solutions to architects complex requirements. Also, the produced documents perfectly match the needs of the workshop and our clients.

J-C MASBOEUF: Once adapted to our needs, Advance Steel has proved to be very easy to use simultaneously allowing us to deal with projects even more and more complex and atypical.

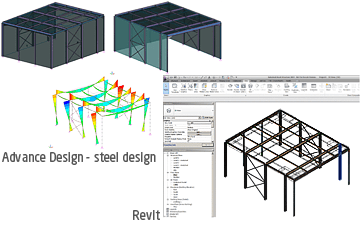

CAD Digest – review of GRAITEC Advance’s BIM Capabilities for Structural Design

CAD Digest, one of the most popular online sources for CAD, CAM & CAE articles, reviews the capabilities of the GRAITEC ADVANCE suite as a complete solution for structural design.

The author of the review, Protim Banerjee (with 15 years of experience in construction management, structural engineering and AEC software development) provides an overview of the GRAITEC ADVANCE suite, highlighting the pros as well as the cons for compatibility and data exchange with Revit Structures 2012.

GRAITEC ADVANCE and Revit Structures have been compatible since 2006, up to the present time. This integration has allowed engineers and design offices using software solutions from both suites to run their structure calculation and drawing creation quickly, without recreating the model and with a minimal risk of errors. As an Autodesk partner for over 10 years, GRAITEC offers an application for Revit Structures – GRAITEC BIM Connect – that ensures the compatibility of Revit models with the GRAITEC Advance suite and with industry standards, such as IFC and SDNF. With GRAITEC BIM Connect, data is imported and exported between applications, using GRAITEC’s own transfer file format – GTC files. The free Revit add-on is available for download here. This add-on generates GTC files for import into GRAITEC applications, and also works as a two-way transfer.

“The Revit add-on allows model synchronization, a tool very useful for comparing the original model with updated ones. The changes that are alerted include member additions (appended), member modifications (modified), and member deletions (deleted); the alerts are made by color coding and by tabulating them in the synchronization dialog. You can review the changes, and then decide whether to accept them” Protim Banerjee states.

GRAITEC BIM Connectt is, in fact, a concept which has constantly improved since 2009. Its key features include data synchronization with the GRAITEC ADVANCE Suite, IFC Interface (Import / Export), CIS/2 Interface (Import / Export), SDNF Interface (Import / Export), PSS Interface (Import / Export). The 3D model is imported from Autodesk Revit Structure (or Autodesk Revit Architecture) to the desired GRAITEC Structural Analysis or Detailing product. To complete the model, a structural analysis and design process is run to optimize the structure, and then synchronized with the Revit Structure model to include any modifications. The implemented elements are structural elements (columns, beams, wall, slabs), custom families containing an analytical model, supports and loads.

“GRAITEC has carefully conceived the overall BIM process with the use of its GTC file format. The concept of cross section mapping and synchronization of changes is certainly very innovative. GRAITEC scores good points when it comes to the software design”, Protim Banerjee concludes, stating also that the GRAITEC ADVANCE suite covers all aspects of structural BIM workflow.

Advance Steel – Sheet and plate metal work

Folded plates of various shapes are widely used in various fields of steel construction: stair ramps for buildings, pipe connection, gas ducts in petrochemical industry, etc. Usually these elements are difficult to model without 3D view, also, obtaining the workshop drawings is a time consuming task.

With Advance Steel it only takes two clicks to create an element, for example, a conical shape from two CAD entities (circle, square, etc.) or between two profiles with different diameters or different sections. All necessary documents (including NC files) are created directly from the model with a simple click. All folded elements are displayed unfolded in workshop drawings which means great cost and time saving.

Below are presented some fragments of the article, to read it full please click here.

Various shapes created in no time!

Automatic tools are available to create plates of any shape. It only takes a few clicks to create a folded element.

All shapes are accepted and can be easily created using a complete set of intuitive tools.

- Rectangular plates (with one central point, two or three points)

- Polygonal plates (created from a polyline)

- Any contour can be cut to get the desired shape

- Holes can be created

Conical and twisted plates

Just two clicks to create a wide variety of complex irregular shapes such as:

- A conical shape from two CAD entities (circle, square, etc.) or between two profiles with different diameters.

- Square – to circular folded elements

- Twisted elements from two curves or splines

Easy to modify while working in 3D

Once created, the folded plate is treated as a single element.

It can be easily modified without loosing the relations between the elements.

Cut any contour

- Create any type of contour cuts on any of the faces or on the folded line

- Create holes of any type: round, slotted, countersink, etc.

- Trim or split any of the joined plates

Add weld preparations

Weld preparations are frequently required for heavy plate fabrication.

With Advance Steel, any chamfer (straight or fillet) can be added to a folded plate edge for weld preparation.

Secure modeling

At any moment it is possible to check if the created plate can be developed into one sheet of material. This insures a correct modeling – very important as Advance Steelcreates automatically the workshop drawing directly from the model.

The unfold representation can be displayed also during modeling.

Accurate drawings created automatically!

Advance Steel automatically creates workshop drawings of all folded plates! All necessary information is included:

- The unfolded representation

- Folding line

- Bending direction

- Folding angle

- Dimensions

Bend allowance calculation

The end-user can control the bend allowance calculation when getting automatic workshop drawings with the representation of the part unfolded.

There are different available choices:

There are different available choices:

- By inner contours

- By outer contours

- By pure median line

- By DIN

- By table

GRAITEC ADVANCE Steel – Before and After Standalone

May and June editions of Roof & Facade Asia,present the versatility of ADVANCE Steel for easy fabrication and erection at site without any errors, either with or without AutoCAD.

Historically based on AutoCAD, Advance Steel is the software solution 100% dedicated to steel construction. It can accelerate the design phase by offering an extensive library of smart objects, automatic joints and specific tools for creating standard structures, stairs, railing and miscellaneous steelwork.

In 2012, the standalone version was released, offering users the possibility to select the desired CAD platform, thus using the software with or without AutoCAD.

May edition of Roof & Facade Asia magazine has a case study for the ADVANCE Steel software solution, used directly on the AutoCAD platform, in the making of Valenciennes Stadium, in France. In short, ETI started using AutoCAD® to draw the firstlines of the project in 2D and submit it to thecontracting owners. The project owner’s and architect’s need to view more precise details in3D the most complex assemblies required the use of Advance Steel, which has a BIM approach. Advance Steel enabled fast modeling of all steel structural elements. From the 3D model, Advance Steel allowed the automatic creationof all fabrication and assembly drawings, with all the necessary labels and dimensions for the workshop.

So, was this easy for ETI? Surely not. The size of the project required four people working full-time on it: one Project Manager, Mr Fabrice Grisot, one Construction Engineer, Mr Stéphane Dottori, and two draftsmen. In order to follow the architect’s wish to have no visible bolts on the structure once the construction is erected, ETI had to design assemblies early from the study phase. Thus, bolted assemblies were designed to ease the transport of parts (that can reach a weight of 10 tons each) and the parts were welded together at site with fastening plates. The welds were then painted and grinded to get a perfect aspect. Therefore, it was necessary to model many weld preparation chamfers on the edges of the plates and the profiles to get a realistic result and, most of all, for these elements to appear clearly on the fabrication drawings.

But was it error free? Certainly seems like it…Mr. Stéphane Dottori, Construction Engineer for ETI Design Office later declared: “We did not receive a single phone call from the site foreman to report any error!”

Well, how great is that!? All the tools are provided for fast and efficient modeling either in 2D or 3D, depending on the user’s preference, subsequently creating all project documents (drawings, lists, NC files), covering every step, from structural modeling, to drawing creation, document management, up to manufacturing and fabrication, with no risk of errors.

So, if the union between AutoCAD and ADVANCE Steel offers so many benefits, why would a Standalone version be better?

First of all, the Standalone version of ADVANCE Steel has many improvements and innovations in functionality, graphics and drawing quality. Second, it features the very well known ‘Ribbon’ interface, for model ‘creation’. Of course, so does AutoCAD, even with a more polished appearance and hosting the Advance Steel commands to the right of its standard tools, while the standalone version stores the most commonly used commands in the home tab, with more advanced features available further along the ribbon.

But in terms of display modes, the Standalone version “features basic wireframe and flat shaded”, while AutoCAD has a more advanced real time display mode. AutoCAD users will benefit from the ability of the platform to quickly model particularlycomplex curves. “While it is possible to do advanced compound geometry in the standalone version, it will be much quicker to do this in the full AutoCAD.”

So, is the standalone version still a competitive and advanced tool for customers? We hope so. Advance Steel’s ability to make lightwork of complex detailing tasks such as stairs and railings, means there is much potential and also still room for improvement.

Most of all, receiving the advanced features of AutoCAD and at the same time, shaving $4,000 off the overall cost by using Advance Steel Standalone is pretty hard to ignore. For existing AutoCAD users, the learning curve for the Standalone version is very fast, benefitting from good interoperability, built-in rendering tools, good 3D navigation tools and DWF available for design/review and sharing data over the web.

“At the core of the product there is little difference between the two versions. Layers, XREFs and other AutoCAD features are all supported in the standalone version and the workflow inside the products is virtually identical” – June’s edition of Roof & Facade Asia magazine states.

Important notice about your StruCad license

Still not made a decision about your StruCad upgrade?

You may have only upgraded some of your StruCad licenses?

You do have options!

We are aware that StruCad users are faced with some tough decisions regarding software upgrades over the coming months. StruCad is a very good system and we respect your investment in it. We at GRAITEC believe Advance Steel is a highly competent modern 3D modelling CAD system developed for the steelwork industry that will serve all your needs for many years to come.

We would like to help StruCad users protect their investment in StruCad by offering a sensible solution to upgrade their software to Advance Steel.

Our StruCad upgrade offer:

- Advance Steel professional license

- 12 months software maintenance and suppor

- Training (tailored StruCad-Advance Steel transition course)

- No time restrictions for your continued use of StruCad

- Upgrade any of your StruCad licenses, whether they are up to date with maintenance and support or not

- We will upgrade any StruCad license i.e. StruCad Full, StruCad Lite etc to an Advance Steel Professional license with no limits!

- Maintenance and support on-going costs some 50% less than our competitors and the price is fixed for a minimum of three years!

- Training – dates to suit your requirements

- Flexible payment terms with finance option

With 10,000 clients around the world. GRAITEC UK alone have over 800 clients using their software, with 200 + clients investing in Advance Steel, a number which is continually expanding in the UK. GRAITEC’s Advance Steel solution guarantees a future proof investment for all your steel detailing and 3D modelling requirements.

-> To view our Advance Steel 2012 videos CLICK HERE

-> To view client projects CLICK HERE

What our customers are saying:

“Blows other software providers out the water”

Builders Beams, David May

“A project that could have taken four weeks can now be completed in a week”

Rob Miller, IAC Ltd

“Productivity gain will double using Advance Steel”

Mark Simmen, RS Construction

“Using Advance Steel will increase productivity in every area”

Joe Bennett, Roltech Engineering LTD

“Using Advance Steel will increase productivity in every area”

Joe Bennett, Roltech Engineering LTD

“Using Advance Steel will prevent drawings bottle necking the company”

Michael-John Varrall, MJV Design

AEC Day 2012 – Presentation of BIM GRAITEC Advance suite

AppliCAD was founded in 1994 by a team that decided to penetrate the Windows based CAD/CAM market after experience in UNIX-CAD/CAM with SUN Workstation for 4 years. The company started its business with Plant Design Management Software and expanded the product line. Presently, AppliCAD is highly committed to offering customers the best solutions for their requirements. Thereby, it is recognized as The Best Design Technology Expert in Thailand.

With over 15 years of experience, AppliCAD Thailand is a “GRAITEC ADVANCE Authorized Reseller” enriching our Value Added Reseller program. It provides mechanical solutions, architecture engineering and construction solutions, rapid prototype and 3D scan solutions and also plant solutions for a wide range of customers in Asia Pacific.

For the 2012 AEC Day, AppliCAD presented the BIM GRAITEC Advance suite as a complete solution for architects, engineering offices, detailers and fabricators which require global CAD / Analysis & Design solutions. AppliCAD highlighted the GRAITEC Transfer Center (GTC) which allows all the models created with GRAITEC software to be synchronized, with no data loss and no need for data reentry. The GTC is an important step in creating and handling a BIM (Building Information Model).

The main subject of the presentation, however, was ADVANCE Steel and Concrete software, as an advanced modeling and detailing system, easy to use, time saving and cost effective.

You can watch the presentation below, and although it is in Thai, the above summary describes its content.

Another success story – Tesco Superstore, Woolwich, UK

-> Architecture office: Sheppard Robson Architects

-> Structural Engineer: Walsh Associates

-> Master builder: Willmott Dixon

-> Steelwork Design: TSI Structures Ltd

-> Location: London, Woolwich

-> Dimensions: 180m x 85m x 52m

-> Specification: 80,000 sq ft Tesco superstore, various other retail units and 259 homes over 17 stories.

-> Total Build Cost: Woolwich Central – Phase 1 & 2 £400m

TSI Structures undertook the challenge of modelling a 17 story, post tensioned concrete structure for connecting secondary steel to a major new supermarket complex in Woolwich, UK.

The 80,000 sq ft Tesco superstore, various other retail units and 259 homes over 17 stories was a total build cost of £400m. The store opening date was set before construction started, so they were under pressure to complete the project to a tight deadline.

Advance Steel allowed TSI Structures to model concrete slabs, walls and beams. They were able to model the cast in channels, and using Advance Steel meant these elements came across onto the drawings. The DWG file format aided in the approval process.

Adrian Betts, from the TSI Structures LTD design office, explains why Advance Steel was the best solution for the completion of this project: “We would not have been able to produce this building in 3D without Advance Steel’s ability to model external elements such as concrete. We were the only member of the construction team with the ability, software resources and technical knowhow, to fully model the enormous concrete structure in three dimensions. Our model and the 3D drawings were used by the Architect for client presentations. With the AutoCAD base this enabled us to add different material renders to the concrete surfaces creating a more realistic and aesthetically pleasing model”.

Watch this video to see the story behind the project:

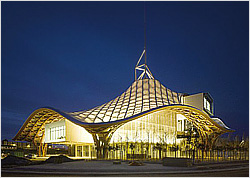

Designed with GRAITEC software, Centre Pompidou was awarded at RIBA 2012

RIBA (Royal Institute of British Architects) Awards have been running continuously since 1966 and are judged and presented locally. No matter the shape, size, budget or location, RIBA Award winning-schemes set the standard for great architecture all across the country. Although more than 50 buildings in the UK won the RIBA Award, only 9 in the EU have won, including Centre Pompidou, calculated with GRAITEC Advance Design.

The Centre Pompidou Metz is a museum of modern and contemporary arts designed by architects Shigeru Ban and Jean de Gastines and located in Metz, France. The Centre Pompidou-Metz is a branch of Pompidou arts center of Paris, and features temporary exhibitions from the large collection of the French National Museum of Modern Art, the largest European collection of 20th and 21st century arts. The museum is one of the largest temporary exhibition spaces in France with 5,000 m2 divided between 3 galleries, a circular shaped restaurant, a theatre, and an auditorium.

The Centre Pompidou-Metz is a large hexagon structured round a central spire reaching 77 meters high, with three rectangular galleries weaving through the building at different levels. The great nave covers 1,200 m² and provides flexibility for the exhibition of large artworks, with the ceiling rising progressively from a height of 5.70 to 18 meters.

The Centre Pompidou-Metz is a large hexagon structured round a central spire reaching 77 meters high, with three rectangular galleries weaving through the building at different levels. The great nave covers 1,200 m² and provides flexibility for the exhibition of large artworks, with the ceiling rising progressively from a height of 5.70 to 18 meters.

The roof is a 90 meters wide hexagon with a surface area of 8,000 m². The roof structure is composed of sixteen kilometers of glued laminated timber, which intersect to form hexagonal wooden units resembling the cane-work pattern of a Chinese hat. The roof’s geometry is irregular, featuring curves and counter-curves over the entire building, and in particular the three exhibition galleries. The entire wooden structure is covered with a white fiber-glass membrane and a coating of Teflon, which has the distinction of being self-cleaning, protects from direct sunlight and also is transparent at night, thus offering viewers a spectacular and unique overview.

GRAITEC supports ‘Virtual Design World Cup’

GRAITEC is supporting FORUM 8, its Value Added Reseller operating in Japan, by providing free Advance Steel and Advance Concrete licenses to the participants of FORUM 8’s 2nd Student BIM and VR Contest open to students worldwide.

The theme of this year’s contest is “The Sustainable Design of a Marine City. The objective is to design a sustainable and self-sufficient Marine City on the sea with innovative designs to overcome the problems all modern cities face in the 21st century.

Work by each and every contestant will be uploaded on FORUM 8’s cloud server, VR-Cloud(R) server, to be judged on its logistics, technical and design aspect, as well as its creativity and how innovative it is. Participants are required to use FORUM 8’s award-winning software UC-win/Road, and at least one other software of their choice from a lineup of BIM and VR software available for free rental during the contest.

Advance Steel and Advance Concrete are among the software the participants can rely on to design and model innovative structure. For this purpose GRAITEC have conceded 50 free short term licenses of both Advance Steel licenses and Advance Concrete for the students. In July 17, Advance Steel and Advance Concrete experience seminars will be organized through 5 cities in Japan (Live-Tokyo TV Conference system- Osaka, Nagoya, Fukuoka. Sendai).

Advance Steel and Advance Concrete are among the software the participants can rely on to design and model innovative structure. For this purpose GRAITEC have conceded 50 free short term licenses of both Advance Steel licenses and Advance Concrete for the students. In July 17, Advance Steel and Advance Concrete experience seminars will be organized through 5 cities in Japan (Live-Tokyo TV Conference system- Osaka, Nagoya, Fukuoka. Sendai).

The Award for the winner is a grand prix worth approximately US$3,600 including scholarship, certificate, World cup Trophy and mementos. Among the rest of the participants, 5 lucky ones will also receive a laptop and every contestants will of course win a participation reward for their work. Applicants have until September 30th to register online. Once they have registered and created their VR model, they will need to submit their work including scripts during the period from October 1st to October 23rd, and once they have submitted their work, they will be notified of the webpage on FORUM 8’s VR-Cloud(R) server to which they can access to browse and test their submitted model, along with their login ID and password. FORUM 8 and special guest judges will come to a decision and determine the winners on November 20th, and they will be awarded in the awards ceremony the following day.

For more information, please contact:

Europe, The Middle East, Americas & Africa: office@forum8.com

Australia, New Zealand & Oceania: anita@forum8.co.jp

Asia and for all other general inquiries: yokoyama@forum8.co.jp

Check out last year’s winners: http://www.forum8.co.jp/english/studentBIM1-Award-e.htm

About FORUM 8

FORUM8, the Japanese 3D software specialist, produces state-of-the-art 3D VR and engineering software. Founded in 1987, FORUM8 is at the forefront of 3D Visual Interactive Simulation (3D VIS) technology and provides 3D VIS capabilities to specialists from various professions, including transportation, engineering, planning, emergency training, architecture, road safety and many more.

For more information, please visit www.forum8.com

How Advance Steel can help your business profitability

In 2010, an article written on www.submityourarticle.com stated that the ultimate aim of specialized steel detailing software is to increase a company’s bottom line profit. But in 2012 what was a concern for steel fabrication businesses, steel engineering companies and even self-employed steel detailers has now become a fact. Those who have the most competitive steel detailing software solution are the ones that are the most profitable on such a dynamic market.

In short, investing in a steel detailing software helps you save time, optimizes your resources and reduces costs with materials and labor. A good example is given by one of our customers, Nial BALL from Westbury Park Engineering which worked with ADVANCE Steel for a boat mold structure (35-40 m long steel structure for fiberglass bouts). He states: “With three days to go before ‘D Day’ our TWO men arrived on site with the pre-fabricated assemblies and in TWO days the structure was erected and we were home in time for tea with a day to spare. Thanks to ADVANCE Steel, we knew the structure would fit long before we arrived on site.”

Off course, not all projects can be finalized in two days using just two men, but reducing the time spent on a very complex project from maybe three months to three weeks is not that bad either. Gheorghe CEPRAGA, engineer at UZINSIDER ENGINEERING, has been working with ADVANCE Steel at his most recent project – assembly of new elements (stairs, railings and platforms) on an existing structure in the ArcelorMittal steel plant. For him,the decision was clear: “I have been working with AutoCAD, especially in 3D view, for a very long time now. I think it is safe to say that it would have been very difficult for us to model the entire structure in AutoCAD. Without ADVANCE steel, the execution would have taken too long”.

Off course, not all projects can be finalized in two days using just two men, but reducing the time spent on a very complex project from maybe three months to three weeks is not that bad either. Gheorghe CEPRAGA, engineer at UZINSIDER ENGINEERING, has been working with ADVANCE Steel at his most recent project – assembly of new elements (stairs, railings and platforms) on an existing structure in the ArcelorMittal steel plant. For him,the decision was clear: “I have been working with AutoCAD, especially in 3D view, for a very long time now. I think it is safe to say that it would have been very difficult for us to model the entire structure in AutoCAD. Without ADVANCE steel, the execution would have taken too long”.

Can it be that simple? Sometimes, time saving leaves room for errors. Not a problem because ADVANCE Steel drastically increases productivity and drawing quality even for the most complex and unusual projects, while reducing the risk of errors.

For the Bregenz festival in Austria, Bregenzer Festspiele fascinated with a spectacular stage engineering, resulting in the biggest sea stage in the world (17m long, 15m wide and 15m high),portraying Jean Paul Marat, one of the leaders of the French Revolution. The construction of the head was connected to a steel construction which was already located at the sea stage.

Although, ultimately, the best steel detailing software is the one that addresses the business’ needs and issues, ADVANCE Steel can efficiently accelerates the design phase (either single or multi-user mode) by offering an extensive library of smart and efficient objects, automatic joints and specific tools for creating standard structures, stairs, railing and miscellaneous steelwork. For the renovation and extension of TIGNESPACE Center, a sports complex equipped with modern multipurpose structures, Thierry Depollier, Eng, at Ets BOUCHET states: “The ability of ADVANCE Steel to work in realistic mode together with 3D navigation have greatly facilitated our work and have improved the efficiency of our weekly meetings with the other disciplines. It is worth mentioning that the fabrication of the welded beams at workshop was simplified with the high-quality drawings automatically created “.

Functionality-wise Advance Steel detailing software has everything you would expect from a specialist structural steel detailing package. Ultimately, what makes ADVANCE Steel special is its accessibility to any type of company which is interested in investing in steel detailing software.

Advance Design webinar

Structural Engineers:

Do you need to use Eurocodes and reduce project time?

on Thursday, May 15th, 2012 from 09:00 to 09:30 CET or 17:00 to 17:30 CET

| Register online for this webinar |

Advance Design® is specifically dedicated to structural engineers who require a professional and easy-to-use solution for simulating and optimizing all their projects. Advance Design® includes a user-friendly structural modeler, automatic load and combination generators, a powerful FEM analysis engine (static, dynamic, time history, non linear, buckling, large displacement analysis, etc.), comprehensive wizards for designing concrete and steel members, and efficient result post-processing and automatic report generators. It automatically updates all reports, including graphical results when modifications are made to the model.

Advance Design TOP 5 benefits:

1 – Powerful modeling system dedicated to engineers: realistic rendering, floors managements for buildings, complete library of user-definable structural elements, load generator, etc.

2 – Advanced analysis features: automatic mesher, time history analysis, static, dynamic, non linear analysis, etc.

3 – Latest versions of Eurocodes implemented: automatic design of concrete and steel elements according to EC1, EC2, EC3, EC8, with 3D interaction curves, deflections checking, buckling and lateral buckling checking, connections design, etc.

4 – “Result Memory” technology: avoid repetitive tasks by updating automatically all the post-processing documents (views and reports) when changing the 3D model.

5 – BIM and Collaborative work: DXF / DWG / Revit imports, multi-user technology, BIM approach for data synchronization, interoperability with industry standards (SDNF, CIS/2, IFC), etc.

Internationalization is a major theme of version 2012 of Advance Design® with the implementation of several new National Appendices to the Eurocodes 0, 1, 2, 3, 5 and 8.

Internationalization is a major theme of version 2012 of Advance Design® with the implementation of several new National Appendices to the Eurocodes 0, 1, 2, 3, 5 and 8.

This version also allows users to go further in the application of the Eurocodes with its many additional features: management of buildings open to the wind, design of timber structures to EC5 or calculation of cracks as a function of applied reinforcement to EC2.

Advance Design® is the indispensable tool for the design of large scale projects.

Boat Mould Structure – Customer project

Nial Ball, Westbury Park Engineering: “This contract was something a bit unusual and was carried out for a prestigious UK based boat building company. I say boat, but I suppose technically they were ships being 35 – 40 metres long! The problem was turning a mould following manufacture in order to release the boat from the mould. Being fiberglass it isn’t such a good idea to have the mould flex and crack the finished boat deck.

The steelwork for the project was designed and built around a 3D surface model supplied by our client and converted for AutoCAD by Graitec. The strange thing about surface models is that the surface isn’t actually there, well not in a solid drawing sense, but I was able to draw a series AutoCAD construction lines from key points on the surface model using XEDGES etc. Once the construction lines were in place the remaining structure was a breeze using Advance Steel. There were no major issues and the model was completed in three days and all drawings were created within the week.”

|

|

“The client was showing some concern with less than a week before the first mould had to be turned and released that we were not on site to install the steelwork. It seems that formerly the installation took seven men and two to three weeks as the structure was fabricated on site and in situ. With three days to go before ‘D Day’ our TWO men arrived on site with the pre-fabricated assemblies and in TWO days the structure was erected and we were home in time for tea with a day to spare. Thanks to Advance Steel we knew the structure would fit long before we arrived on site, the structure could be built in manageable sub-assemblies and with bolted joints there was no need for any welding on site.”

|

|

Webinar “Discover Advance Steel 2012” planned for May 3rd 2012

Steel detailers, Structural Engineers:

Discover Advance Steel 2012: The Powerful and Affordable Steel Detailing Software

on Wendsday, May 3rd, 2012 from 9:00 to 9:30 am CET or 5:00 to 5:30 pm CET

| Register online to this webinar |

Advance Steel® is specifically designed for professionals who require an easy-to-use 3D structural steel detailing software that automates the production of drawings, BOMs and NC files.

Advance Steel® is part of the GRAITEC structural BIM solution, automating the entire structural design process, from engineering design to detailing and fabrication.

Advance Steel TOP 5 benefits:

1 – More Productivity with the flexible and efficient 3D modeling automatic tools: complete international catalogs, library of parametric joints, single or multi-user mode, etc.

2 – Short learning curve: reduces new employee ramp up time

3 – Specific features for miscellaneous steel and sheet metal: automatic functions for all type of stairs and railings, automatic tools for sheet metal creation, folded and twisted plates, etc.

4 – Precise and automatic creation and updating of construction documents: BOMs automatically created from the 3D model, revision control, revision clouds, drawing presentation template, automatic drawing scaling, paper formats and views, etc.

5 – BIM and collaborative work: DXF / DWG / Revit imports, multi-user technology, interoperability with major industry leading detailing / fabrication / engineering / MRP packages (CIS/2, SDNF, DSTV, KISS, etc.), etc.

Historically based on the AutoCAD® platform, Advance Steel® 2012 allows users to use their software with or without AutoCAD®. In fact, the product includes its own graphics engine, and the user can select the desired CAD platform. Regardless of the selected platform, all the essential functionality of the software is retained, as well as DWG® compatibility.

This major change has also allowed GRAITEC to simplify the user interface by focusing on and organizing the industry specific functionality of the software.

Another major impact for users: the overall cost of the solution and the ease of installation and deployment. The return on investment for the current version is improved by 30%.

Great feedback from one of our clients in UK

Will Rudd Davidson Edinburgh & Glasgow is one of Scotland’s leading Structural and Civil Engineering Consultancies. The Company has 25 skilled Engineering staff working with the latest technology and within a Quality Management framework, providing a high standard of service, professionalism and flexible response to requirements. With Associates based in Edinburgh, Glasgow and London, the Company can call on approximately 35 technical staff to address the challenges of larger scale commissions throughout the whole of the UK.

Will Rudd Davidson Edinburgh & Glasgow has been working with GRAITEC software for several years now and their response for the support and consulting services they received was rated: EXCELLENT.

Alistair Crawford, Will Rudd Davidson Edinburgh & Glasgow spokesperson, declares: “GRAITEC support is the standard by which I judge other companies. Whilst many have improved over the years I still consider GRAITEC to be the level they should aspire to. Having a dedicated UK call and support centre is also a good ace to have up your sleeve.”

GRAITEC offers its users a wide range of servicesto optimize productivity: complete service maintenance, phone, fax and E-mail based technical support, interactive live web support, general and custom training, special project assistanceand consulting services, CAD/design projects, custom software development and many others.

You can visit our Support page for more information, or take a look at GRAITEC Advantage to see all the services included in our maintenance contract.

Here are some of the projects done by Will Rudd Davidson Edinburgh & Glasgow:

Advance Steel: Effective use of Joint Tables

Watch this video tutorial on how to set up joints to be configured automatically so you don’t need to constantly adjust settings.