Watch this video tutorial on how to set up joints to be configured automatically so you don’t need to constantly adjust settings.

steel detailing

Advance Steel for StruCAD users

Advance Steel, the alternative solution to StruCAD

- Proven track record with more than 10,000 seats worldwide: Trusted market confidence

- Rapid adoption rate resulting in +50% growth in licenses in 2011: Tried and tested solution

- Increased functionality / productivity: Tools for all market sectors: BIM, Structures, Off-shore, Bridges, Architectural, Sheet-metalwork,…

- Works as a standalone application or with AutoCAD: Flexibility for users to choose platform to that suits them – no need to have AutoCAD

- Low initial financial outlay: Best value system on the market

- Lower on-going cost of ownership: Premium support & maintenance less than half the price of other systems

- Easy to use and short learning curve: 5 day foundation training course; 3-days transition training from Strucad, includes full training manual

- Quick and easy deployment: Set up company drawing borders in minutes

- Interoperability: DSTV NC files in all versions, IFC, SDNF, CIS2, Graitec BIM, KISS, PSS, …

- Support and Helpdesk service rated 98% excellent or good by our users: Dedicated team ready to help you by phone, email or remote assistance

Advance Steel 2012 videos

| Advance Steel 2012 – Easy and efficient modelling tools |

|

| Advance Steel is a complete 3D BIM steel detailing software providing automatic and user-friendly tools for creating the 3D model of your building in the best time. From the creation of the portal frames to the generation of all cladding profiles, Advance Steel comes with numerous easy-to-use tools for purlins, side rails, automatic connections, stairs, railings and much more! |

| Advance Steel 2012 – Navigation through a 3D model |

|

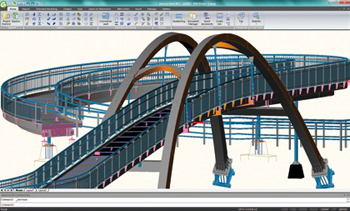

| See how user-friendly and powerful Advance Steel 2012 is to navigate through a complex pedestrian bridge (model courtesy of PKD, Czech Republic). |

Customer Projects

GRAITEC will be exhibiting at NASCC 2012 in Dallas, Texas, April 18-20, 2012

March 22nd, 2012. GRAITEC is pleased to announce that the GRAITEC North American team will be exhibiting at NASCC, the steel conference in Dallas, Texas, on April 18-20, 2012 at booth #610.

March 22nd, 2012. GRAITEC is pleased to announce that the GRAITEC North American team will be exhibiting at NASCC, the steel conference in Dallas, Texas, on April 18-20, 2012 at booth #610.

The GRAITEC team will be demonstrating Advance Steel 2012, the powerful and user-friendly 3D structural steel detailing and fabrication software that automatically creates drawings, BOMs and NC files, and that communicates with Autodesk® Revit® among other systems.

Version 2012 of Advance Steel provides the user with the choice of CAD platform, AutoCAD or the GRAITEC CAD platform. The team will be demonstrating Advance Steel with both platforms at the NASCC.

GRAITEC will also be demonstrating Advance Design 2012, a superior solution for the structural analysis and design of Reinforced Concrete, Steel and Timber structures according to the latest versions of Eurocodes and North American codes.

During the NASCC, GRAITEC is offering

3 workshops on Thursday, April 19:

Speed up your BIM 3D modeling for miscellaneous steel and plate work with Advance Steel

7:00 am – 7:45 am – Ft. Worth 1-2

Register Now

Accelerate your steel detailing with Advance Steel easy to use BIM solution

3:00 pm – 4:00 pm – Dallas 1

Register Now

BIM structural steel for the energy industry with Advance Steel

4:15 pm – 5:15 pm – Dallas 1

Register Now

More doors open to Advance Steel

With the shocking Strucad announcement, Strucad users are now faced with a difficult decision – or is it?

For anyone involved in Structural Steelwork, the way GRAITEC UK sees it, there is a clear and easy choice, Advance Steel 2012!

Advance Steel 2012 offers:

– Proven track record with more than 10,000 seats worldwide

- Trusted market confidence

– Rapid adoption rate resulting in +50% growth in licenses in 2011 –

- Tried and tested solution

– Increased functionality / productivity

- New tools for all market sectors: BIM, Structures, Off-shore, Bridges, Architectural, Sheet-metalwork…

– Works as a standalone application or with AutoCAD –

- Flexibility for users to choose platform to that suits them – no need to have AutoCAD

– Low initial financial outlay

- A fantastic GRAITEC UK ‘Switch-offer’

– Quick and easy deployment

- Set up company drawing borders in minutes

– Interoperability

- DSTv NC files in all versions, IFC, SDNF, CIS2, Graitec BIM, KISS, PSS…

– Support and Helpdesk service rated 98% excellent or good by users

- Dedicated team ready to help you by phone, email or remote assistance

The GRAITEC UK branch has never received so many phone calls and enquiries from people looking for an alternative solution to Strucad, and the feedback from those that have already moved to Advance Steel was “easy to use” and “very capable”.

If you have been affected and would like to see more about Advance Steel why not visit www.graitec.co.uk/advance_steel_2012.html or contact one of the Graitec UK team on 0844 543 8888 or email your enquiry to sales@graitec.co.uk

The versatility of Advance Steel can help you realize projects out of the ordinary!

With Advance Steel, our users can create amazing projects. Our American users understand this and have created incredible structures with it. Tuckerman Steel Fabricators Inc. were able to harness the power of Advance Steel to create their latest project, something special that was launched on 11/11/2011 and captured on video. Check it out at Boston Tea Party Ships and Museum-Launching 11 11 2011!

The project shown is a steel barge supporting a 3 story building consisting of shops, a museum, and restaurants, including ballast compartments, stair wells, elevator compartments, watertight doors, gangway support platforms and pile guides. The barge had to be pre-fabricated in panels – deck panels, bottom panels, bulkheads, side panels, and very often panels that included over 150 parts. Accordingly to Ilko Dimitrov, Project Manager at Tuckerman Steel Fabricators Inc., Advance Steel increased the productivity and the accuracy of the drawings: “The software was very helpful in detailing the panel drawings and all the interior framing and stairs as well”.

Also, the designers of the barge noticed that Advance Steel is very well designed to optimize drawing layout by eliminating empty spaces between members, and has the option to create running dimensions from left to right and vice versa, and the option to switch between absolute and relative or both types of dimensions. The scaling of objects is very easy. Placing labels, part marks, material type and basically all necessary information is very handy. Creating and updating BOM is fast and accurate.

Tuckerman Steel Fabricators, Inc. based in Boston, MA is incredibly proud of the results obtained with Advance Steel. The week after they were trained on Advance Steel they were able to model and detail the entire barge. They were able to meet their fabrication and shipping deadlines without any errors!

GRAITEC launches its Czech website

AB Studio is pleased to announce the launch of the new Czech GRAITEC website, thus making the Advance suite, but also CADKON and TREPCAD, available to engineers and structural draftsmen in Czech Republic and Slovakia.

While looking for comprehensive and easy to use detailing software solutions, consider CADKON (link to http://www.graitec.cz/cadkon.html), a convenient and powerful tool with simple controls, specifically designed for creating advanced construction drawings, and now can be run as a standalone application.

The website provides information on the GRAITEC ADVANCE suite, with its many new features and improvements included in the 2012 versions, with special focus on the Czech version of Advance Design (http://www.graitec.cz/produkty-advance/advance-design.html) and the fact that starting from the latest version, Advance Steel (http://www.graitec.cz/produkty-advance/advance-steel.html) breaks free from AutoCAD.

Another novelty for Czech users is the Czech version of TREPCAD, a dedicated and comprehensive stair modeling and detailing software that will be available to Czech customers in March, 2012.

The website also includes a customer reference section (link to http://www.graitec.cz/reference/), where there is information about our clients remarkable designs – the most elaborate projects made with ADVANCE or CADKON software solutions can be viewed.

AB Studio, a part of the international GRAITEC Group and one of the largest suppliers of CAD / CAE solutions in the Czech Republic, invites you to visit us at www.graitec.cz!

Another success story: customer in Canada thrilled to work with Advance Steel

A recognized and expanding company in the manufacturing of steel structures and wrought metals situated in Quebec (Canada), Pro-Mec Elite Inc., has chosen GRAITEC Advance Steel 2012 as its steel detailing software.

Pro-Mec Elite Inc. was using AutoCAD and Inventor so far to do all their studies. They recently decided to move to a 3D BIM solution in order to gain productivity with their drill-line from Ficep and analyzed all software available on the market.

After an extensive review of several software packages such as TEKLA Structures, SDS/2, and StruCAD, they found that Advance Steel is much easier to use and with the advantage to be based on AutoCAD.

GRAITEC Inc. had different meetings with Pro-Mec Elite Inc to answer their expectation and demonstrate that Advance Steel is the right solution for the type of structures they are daily doing.

Therefore Pro-Mec Elite Inc. decided to purchase 2 seats of Advance Steel (with the potential to acquire 4 additional licenses as 6 detailers are working the company) and followed the training 2 weeks ago in the office of GRAITEC Inc (Montreal).

Already, after only 1 week using Advance Steel, they noticed a significant time gain in the realization of drawings and are very satisfied with the software and customer service at GRAITEC.

More information on Pro-Mec Elite Inc. website: http://www.promecelite.com/news/purchase-of-graitec-advance-steel_12

Advance Steel 2012: CAD platform freedom

Advance Steel® is specifically designed for steel professionals who require an easy-to-use 3D structural steel detailing software for automating drawing production.

Choice of graphical platform and improved ergonomics

Historically based on the AutoCAD® platform, Advance Steel 2012 allows users to use their software with or without AutoCAD®. In fact, the product includes its own graphics engine, and the user can select the desired CAD platform. Regardless of the selected platform, all the essential functionality of the software is retained, as well as DWG® compatibility.

This major change has also allowed GRAITEC to simplify the user interface by focusing on and organizing the industry specific functionality of the software and the BIM integration. A “BIM Center” facilitating data exchange is available.

Another major impact for the user: the overall cost of the solution and the ease of installation and deployment. The return on investment of Version 2012 is improved by 30%.

New automatic controls for 3D modeling

Version 2012 also has many other improvements, the main ones are as follows:

- Management of a preliminary reference mark to improve the traceability of elements from their creation to manufacturing

- Option to group similar connections to manage and change them in a single operation

- Implementation of new automatic connections (e.g., turnbuckle bracings, purlin connections with sleeves, connections between steel and concrete elements)

- All new connections work on standard and cold rolled profiles

- Numerous modifications in the existing connections, including in the field of metalwork.

- Cold rolled profiles ( Joris IDE, Kingspan, etc.)

- Cladding sections (Perfitec, Metecno, Corus, etc.)

- Bolts and connectors (Lindapter, Australian bolts, etc.)

- Several new drawing styles delivered and ready to be used

- Lists on drawings can be customized to include formulas (e.g. elements weight + 5%)

Movable overland tripper detailed with Advance Steel

Clinton Dantu, the CEO of Dantu Drafting cc. (South Africa), explains why Advance Steel was the right tool to handle this complex project and for creating all detailed drawings.

“Dantu Drafting cc. is a registered company formed five years ago to meet the high demand for an independent drawing office not affiliated to any particular Consulting or Engineering firm. We entered the market with many years of experience in Materials Handling, Process plants and Heap Leach layouts. We added detailing to our résumé as we found managing the drawing work from layout to fabrication gives us the edge over any of our competitors and speeds up the completion time of the job as a whole. We have been using Advance Steel for the past four years and we are really impressed with its 3D modelling capabilities and the speed with which one can complete any project.”

“The Movable overland tripper (mot) is a hydraulic driven and steered machine. We used wheel mounted Bonfiglioli 713 c3b with brake and disengagement planetary 142:1 gearboxes. The mot will be used in Zambia at Luanshya copper mine, to feed a heap leach system. The total mass of the machine is 45 tons with a total length of 38 meters and a total height of 9 meters. The mot is needed to be an all-wheel drive machine, as it runs above a 900 wide overland conveyor over uneven terrain.“

“We used Advance Steel for this project so we could do all our layout work in 3D and still easily supply the client and designers with 2D AutoCAD® drawings from which we could all sit around a table to discuss the concept. After our meetings we could update our 3D model to suit any comments and so update our 2D AutoCAD® drawings in time for the next meeting. Having the model proved to be a great tool in getting any new parties involved up to speed with the project, just by showing them the model they would get an immediate insight in to the project. Once the mot’s concept was approved and the design was complete we could continue with creating the connections and then the shop detail drawings. With a certain amount of input we could update our shop drawings to suit our fabricators requirements.“

“Using Advance Steel for this project helped us speed up the design time for the mot as we had a constantly updated model to keep all involved with the project informed of our progress and ideas. By using Advance Steel as the 3D steel detailing application, productivity gains of over 25% were realized, compared to using regular AutoCAD®.“

Engineering office: Dantu Drafting cc (South Africa) – http://dantudrafting.com/

Project: Heap leach project

Client: Luanshya copper mine

Location: Muliashi Copper Mine (Zambia)

Advance Steel Project: Mugam Evi Concert Hall

Here is a great example of GRAITEC’s versatile modeling BIM software ADVANCE Steel : Mugam Evi Concert Hall

Project location: Baku, Azerbaijan

Design Office: NCA Container- und Anlagebau GmbH

Project description:

The concert hall consists of 500 tons of steel. A specific feature of the project was the creation of the whole steel construction. The construction mainly consists of three-dimensional rolled pipes. Additionally each single pipe had elliptical-shaped radii on two levels. The parts of the steel construction had to be connected in an elegant way, to give the building a perfect façade. First, the steel parts were prefabricated in the workshop of NCA Container- und Anlagenbau GmbH. The Steel parts were finally welded together, to have a smooth connection between the main bars.

Successful Advance Steel User meeting in Netherlands

A user meeting was organized by MATRIX Software, the GRAITEC reseller of Advance Steel in Netherlands on the 29th November for the users from Netherlands and the Flemish-speaking area of Belgium. More than 50 end-users were present at this event which took place in Gorinchem (Netherlands).

The companies Stageco&Breetec explained in details how they successfully used Advance Steel to model in 3D the impressive stage of the U2 Tour.

Matrix software finished the meeting with the presentation of prizes for the 3 best projects in their 2011 Advance Steel User competition.

Marc Verstraten (from Breetec company), winner of the first prize in the 2011 user contest, explains: “Advance Steel was the right software solution to handle the type of complex project for the conveyor for Arcelor-Mittal, and although the project did not use a lot of the standard connections from Advance Steel, it still was possible to create the complete model with Advance Steel objects. As more than 50% of the project consists of folded plates we were especially satisfied with the Advance Steel bending and unfolding capabilities, plus also the drawings that Advance Steel produced more than met the accuracy requirements for this type of construction.

We are very proud to win the first prize in the 2011 user contest. It confirms that smaller companies can produce complicated designs and thereby acurately achieve the higher level of complexity required in so many modern design. We will keep improving our skills with Advance Steel by pushing ourselves and the program further to the limit. ”

The High End Steel Detailing Solution used in the construction industry in Turkey

In October 2011, ÇEKA Ltd, a market leader in steel formworks, has chosen to use GRAITEC Advance Steel. By using GRAITEC solution for modeling and detailing the steel structures since version 7.1, ÇEKA decided to speed up the time allocated to its projects with the new integrated intelligent functionalities. Thus, the engineers feature the Multi-User solution, which allows them to work simultaneously on the same project by assuring a secure data transfer between all 10 working stations.

Zerrin Kutay, Vice President of ÇEKA Ltd.: “The market demands more and more complex formworks and faster than before. Engineering design is a critical step in our production process and Advance Steel has been an integral part of our success since we first started using 5 years ago on a limited scale. We have now decided to extend the Advance Steel to all levels of engineering design and we are confident in Advance Steel’s continuing contribution to our success in capturing market growth.”

Ionel DRAGU, General Manager of GRAITEC Romania : “We are strongly confident about this cooperation with ÇEKA, which certainly will be the first step to our extension in the Turkish market. Moreover, we will be glad to share the success stories of ÇEKA, due to the use of Advance Steel.”

About ÇEKA:

In Turkey, the year 1976 in which ÇEKA has been established, the construction industry was not acquainted with the industrial formworks. In those years, limited number of companies which were in search of new technologies had worked with ÇEKA.

Since then, ÇEKA is serving the growing demand by increasing the production capacity and introducing newer technologies in design & productions as well as complementary services like the sub-contracting, steel formwork rental services, along with offering products of the firms that ÇEKA represents. Within the range of limited firms, which use their own patent, technology and design, ÇEKA dwells on the design and production of more practical and more economical formworks. ÇEKA formworks, the result of 30 years of construction site experience, are designed within TS, DIN and ACI norms and been used by the constructors in Turkey and abroad.

For more information, visit: www.ce-ka.com.tr

Service Pack 1 of Advance Steel 2011

Service Pack 1 of Advance Steel 2011 provides the following to end-users:

• Various enhancements

SP1 makes Advance Steel 2011 compliant with AutoCAD® 2012 and AutoCAD Architecture® 2012

AutoCAD® 2012 enables the quick creation of documents from a variety of modeling formats, helping to reduce manual documentation workarounds. Capture and import as-built information to jump-start your design process. Plus, you’ll find a wide range of timesaving enhancements to the features you use most. AutoCAD® 2012 delivers the powerful tools you need to participate in smooth 3D design workflows, helping drive your projects to completion more quickly than ever before.

Service Pack 1 has different enhancements such as:

![]() Shim plates in base plate joints can be created with or without a leveling plate.

Shim plates in base plate joints can be created with or without a leveling plate.

Online Live Demo for GRAITEC Advance Steel dedicated for the Turkish market

Following an increasing interest from the Turkish market, on 9th of November 2011, starting at 10.30 EEST, a Live Demo for Advance Steel 2011 will take place. This presentation, which will be held in Turkish language, is addressing to all specialists, engineers and drafters involved in the structural engineering domain from this market.

Following an increasing interest from the Turkish market, on 9th of November 2011, starting at 10.30 EEST, a Live Demo for Advance Steel 2011 will take place. This presentation, which will be held in Turkish language, is addressing to all specialists, engineers and drafters involved in the structural engineering domain from this market.

This is for the first time when GRAITEC holds a dedicated webinar for the Turkish market, due to a continuous economical growth during the last decade, especially in this domain.

Anyone can subscribe to this live presentation by accessing the link bellow:

| Register online for Wednesday, 9 November 2011, 10:30 EEST live demo – in Turkish |

All the participants will get in touch with the use of GRAITEC Advance Steel which accelerates the design phase by offering an extensive library of smart objects, automatic joints and specific tools for modeling and detailing any kind of steel structures, stairs, railings and miscellaneous steelwork.

For more details, you can check this page (info in English) or this page (info in Turkish).

steeldetailingsoftware.co.uk recommends ADVANCE Steel

According to www.steeldetailingsoftware.co.uk, ADVANCE Steel is the best choice for steel detailing and steel engineering software, after closely analyzing the main key software selection criteria: cost, profitability and functionality.

According to www.steeldetailingsoftware.co.uk, ADVANCE Steel is the best choice for steel detailing and steel engineering software, after closely analyzing the main key software selection criteria: cost, profitability and functionality.

The website states that Advance Steel is exceeding other software like Tekla or StruCad (which have significantly larger backgrounds in steel detailing and engineering) when it comes to interoperability with other platforms, functionality and drawing output. What they consider to make this software special is its accessibility to any type of company which is interested in investing in steel detailing software.

As they say, Advance Steel has a far shorter learning curve than its competition, fabrication and drawing output “is exceptionally flexible” and offers businesses in this sector an affordable solution. “Functionality wise Advance Steel detailing software has everything you would expect from a specialist structural steel detailing package […]”, its adaptability evolving trough time, becoming more appealing to customers.

Although, ultimately, the best software is the one that addresses the businesses needs and issues, their conclusion is that “Advance Steel is a clear winner using the selection criteria adopted as this applies to most businesses seeking increased productivity and profitability gained from the adoption of specialist technology[…]”.

Advance Steel Project: Steam Cracking Furnaces

HEURTEY Group is the World largest independent group with a presence in 34 countries. Heurtey is an expert in design & fabrication of Process Fired Heaters Refining, Petrochemical and Hydrogen Industries.

In September 2009, the HEURTEY Group won a major contract in the Petrochemicals sector on behalf of Total Petrochemicals. This contract covers the supply of two ethylene cracking furnaces for the Gonfreville plant in Normandy and is part of a modernization project of the steam cracker during next turnaround scheduled in September 2011. Heurtey Petrochem has used technology from Shaw Energy and Chemicals (Stone & Webster) to complete this turnkey contract, which includes on-site assembly work.

Heurtey Petrochem Romania is the main detailing design office of the HEURTEY Group, fully involved in this project, with 30 engineers and technicians specialised in the mechanical design of furnaces and trained in the use of GRAITEC Advance Steel 3D design software.

The two furnaces, pipe rack and steel structures are prefabricated and manufactured by Beta-Heurtey, the Group’s Romanian fabrication workshop.

Delivery of the furnaces is planned for July 2011.

Location: Gonfreville Refinery, France

Design office: Heurtey Petrochem SRL Romania

Beneficiary: Total Petrochemicals

Technology: Shaw Stone & Webster

Cluj Arena Stadium

Cluj Arena stadium aims to be one of the most modern stadiums in Romania. The project must be completed this autumn.

The construction is at the location of the old Ion Moina stadium. With a capacity of over 30.200 seats, the developers say this is more than a stadium: it is the biggest sports and leisure center in Romania, with a shopping and dining area as well.

The initial project underwent several changes: the total capacity of the arena has reached 44.000 m2 (from 22.000 m2) and the running track will have eight lanes, not six, as initially expected.

“It is more than a stadium; it is the new landmark of the city, in which we managed to capture the passion, the emotions and most of all spirit of fair-play” Mr. Florin Dico

Construction company: Dico and Tiganas Office Design Cluj-Napoca

Design office:

Cluj-Napoca Technical University,

Dico and Tiganas Office Design Cluj-Napoca,

Bogart Construct Cluj-Napoca,

DAS Engineering Group

Keep track of changes during the project revision stage

Often, during the review stage of a project, different changes might be necessary such as:

– New details (views) added on the drawing to provide additional information

– Model modifications such as element geometry, element position, material, new elements

Model modifications affect the existing drawings. Since there are several people involved in the review process, it is useful to keep track of the changes made.

Standard practice

According to standard practice in maintenance of engineering drawings, changes made in the model during the review stage of a project are identified using a number or a letter code and are listed in the revision table on the affected drawing. For each revision level, the revision table lists the reviewer (author) and a short description of the change made. Additionally, revision clouds are used to draw attention on modified areas of the drawing.

CAD techniques

Using simple CAD software, the elements are modified and revision clouds are drawn manually – a task that requires patience and significant attention to mark and then locate the changes in the drawing. The revision table is drawn using simple entities (lines and text) and updated manually. Additionally, a document management system can be used for drawing revision control.

Advance Steel – Easier revision management

Detailing software like Advance Steel allows keeping track of the changes in drawings similar to traditional revision control, but with a lot of improvements in the workflow:

- Drawing update

- History and backups

- Tracking of changes in the revision table

- Marking changes using revision clouds

New Valenciennes Stadium modeled with Advance Steel

The new stadium in Valenciennes, France, is located near the original one, and has a 25000-person capacity. It is meant to host the Valenciennes Anzin Football Club’s games. ETI Design Office, which has experience in designing several stadiums, is in charge of this project. In addition to the project’s size, the expectations of the Architecture’s Office – with the major constraint of not letting any bolts appear on the steel structure – have called for the use of Advance Steel for easy fabrication and erection at site without errors.

The conception of the new Valenciennes Stadium has required the expertise of ETI Design Office, which managed the complete study of the Alps stadium of Grenoble (France) in 2006 and worked on the extension of Marcel Picot stadium in Nancy in anticipation of the Euro 2016 football cup that will take place in France. The size of the project required four people working full-time on it: one Project Manager, Mr Fabrice Grisot, one Construction Engineer, Mr Stéphane Dottori, and two draftsmen.

About the use of Advance Steel

ETI started using AutoCAD® to draw the first lines of the project in 2D and submit it to the contracting owners. The project owner and architect’s need to view more precise details in 3D about the most complex assemblies required the use of Advance Steel, which has a Building Information Modeling (BIM) approach.

With the flexibility of its numerous tools, Advance Steel enabled fast modeling of all steel structural elements, whether by using integrated libraries of standard sections or by using the automatic conversion tool that allows converting AutoCAD® elements into polygonal plates.

A steel structure without any visible bolts

In order to follow the architect’s wish to have no visible bolts on the structure once the construction is erected, ETI had to design assemblies early from the study phase. Thus, bolted assemblies were designed to ease the transport of parts (that can reach a weight of 10 tons each) and the parts were welded together at site with fastening plates. The welds were then painted and grinded to get a perfect aspect. Therefore, it was necessary to model many weld preparation chamfers on the edges of the plates and the profiles to get a realistic result and, most of all, for these elements to appear clearly on the fabrication drawings.

From the 3D model that is automatically numbered, Advance Steel allowed the automatic creation of all fabrication and assembly drawings, with all the necessary labels and dimensions for the workshop. In addition to the drawings generated as DWG files that can be easily read by the architect, the steel parts could be directly transferred as DSTV and DXF files to the CNC machines located in the workshop of a subcontractor in charge of the fabrication of the structure.

Assembling the steel structure without errors

The assembly drawings generated from the 3D model included all the necessary 2D and 3D views for the assembly teams to perfectly understand everything at site. Since all verifications of clash detection were applied on the Advance Steel digital 3D model, no adaptations at site were needed during the erection of the structure.

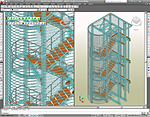

Advance Steel – Stairs and Railings

With its advanced feature set, Advance Steel supports the design of complex structures such as straight and spiral stairs, railings, cage ladders, etc. Advance Steel creates all necessary documents (including NC files) for the stair fabrication using a user selected template.

Quick and easy

Once the user selects 2 points, the stair with its stringer and treads (including connection to the stringer) is created.

The tread distances are calculated using a standard formula for determining the ergonomic height and length of the step.

The stair can be modified using profile types for stringers, connection types between the treads and the stringers, lower and upper landing

Instant railings

Once the stringers are selected, the railings are created using the user defined start and end points.

Railings of any type can then be modified. Features include:

- Profile types for posts, handrail and kickrail

- Controlled positioning of posts, top handrail, middle handrail and kickrail

- Connection between posts and stringers

- And more…

If the stair length and width are modified the railing is automatically updated!

Spiral stairs

Using the Advance Steel advanced tools, with a few clicks defining the height, the tread width and direction, the entire stair can be created. Various options are available:

- Large library of tread types

- Treads can be welded to the central post or connected by a profile or a bolted plate

- And more

Cage ladders

All elements of a cage ladder are inserted by two points defining the height. The number of rungs can be defined or calculated according to the distance between the rungs. The user can modify then the shape and the size of the elements.

Easy to customize

Stairs and railings can be customized through the Properties dialog box.

The tabs of the Properties dialog box are grouped in logical categories to simplify the use of this powerful feature.

The user can modify the parameters (dimensions, treads types, connection types, etc.) to get the required structure. All modifications are visible in the model as they happen.

Automatic drawings

Once the stair is modeled, the user may select a template for the workshop drawing. Advance Steel then creates all the necessary documents (including NC files) for the stair fabrication. The drawings are automatically labeled and dimensioned. The user can customize the drawing layout using the Drawing Style Manager.