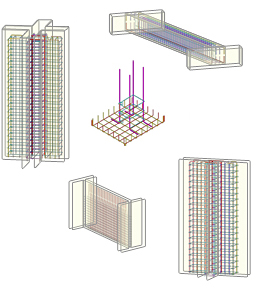

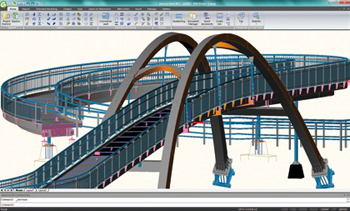

Advance Design® BIM system is dedicated to structural engineers who require a comprehensive solution for simulating and optimizing all their projects. It includes: a user-friendly structural modeler, automatic load and combination generators, a powerful FEM analysis engine (static, dynamic, time history, non linear, buckling, large displacement analysis, etc.), comprehensive wizards for designing concrete and steel members according to Eurocodes, efficient result post-processing and automatic report generators.

Service Pack 1 of Advance Design 2011 has been released and includes many corrections and enhancements for the implementation of the Eurocodes:

Eurocode 1

Improvements to combination management: option to group several load cases, Psi coefficients in the property list of families, option to define several live load types in the same model…

More detailed clause references in the “Description of climatic loads” report:

The “exceptional snow fall” field is now automatically activated when set on A2, B1, B2, C2 and D snow areas (see 1.1 (3) from French National Annex) (Ref. 11381).

Eurocode 2

Improvement: ADVANCE Design can return values for both concrete stresses and steel stresses.

A new option has also been added in order to compute stresses according to French “Recommandations professionnelles”:

When activated, ADVANCE Design will use the same αe value for the three SLS combinations (characteristic, frequent, quasi-permanent):

A new field, “Equivalent diameter Φeq”, has been added in the concrete properties of linear and planar elements.

After the calculation, the values for Sr,max, ξsm-ξcm or wk can be displayed.

The crack width is calculated taking into account the theoretical reinforcement value for the reinforcement ratio calculation. In the Advance Design 2012 release this feature will be improved with the option to define the reinforcement bars on linear and planar elements.

Improvement: The Young’s modulus for concrete materials is computed with the formula from EN1992-1-1 (Ref. 11617).

March 22nd, 2012.

March 22nd, 2012.

GRAITEC

GRAITEC