Westbury Park Engineering are a service Engineering Company specialising in Fabrication, Structural and Mechanical Assemblies together with custom built equipment.

Their experience and diversity from being involved in the industry for more than 20 years has culminated in a wide knowledge and understanding of working practices, technologies and industry requirements.

Westbury Park Engineering have the experience to complete contracts from complete materials handling plants, MOD and Petrochemical Fabrications with full manufacturing traceability to mechanical and custom built assemblies including Hydraulics, Pneumatic, Electrical and CNC systems.

Westbury Park Engineering has been working with GRAITEC software for a number of years now.

Nial Ball, Westbury Park Engineering, recently sent in his comments following a site visit by one of the Technical Support team at GRAITEC UK: “I would like to thank John Bennett for the hard work he did yesterday in re-installing my Advance Steel. I think the work involved was a little more than he had anticipated but my Advance Steel seems to be working so much better now. Thanks again for your commitment to customer service and satisfaction. I can’t imagine that many other companies would be so dedicated to their customers“.

GRAITEC UK are committed to providing customers with the most efficient Technical Support service possible – a first class service our customers have come to expect over the years.

We remain focused on delivering outstanding service, and we are delighted to receive these extremely positive comments.

GRAITEC UK offers its users a wide range of services which can help optimise productivity: complete service maintenance, phone and E-mail based technical support, interactive live web support, general and custom training, CAD/design projects, custom software development and many others.

You can visit our Support page for more information, or take a look at GRAITEC Advantage to see all the services included in our maintenance contract.

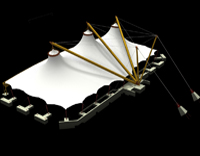

The project consists of the three buildings which make up the centre – the remodeled Victorian vicarage, the classroom block, made of a steel/concrete hybrid design, with a very complicated roof and the Wessex Auditorium, an assembly hall with a complex box section truss design.

The project consists of the three buildings which make up the centre – the remodeled Victorian vicarage, the classroom block, made of a steel/concrete hybrid design, with a very complicated roof and the Wessex Auditorium, an assembly hall with a complex box section truss design.

Internationalization is a major theme of version 2012 of

Internationalization is a major theme of version 2012 of