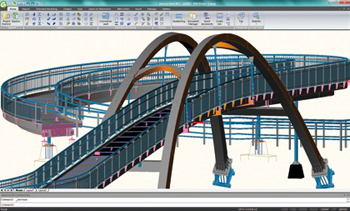

Advance Concrete provides the option to get a single “dwf” file which contains reinforcement elements and the structural model. This file is necessary for importing the structural model into other software like “Autodesk Navisworks“.

The “dwf” file can be created by following two steps:

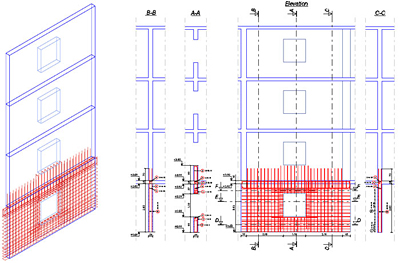

For this example, consider that some structural reinforcements were reinforced using some dynamic solutions.

The first step is to create a file that contains reinforcement bars as ACIS 3D solids.

First, select all the existing entities. These elements can be selected using the “Select by type” option, found on Advance Concrete‘s Pilot. The entities can also be selected by using AutoCAD®’s “Quick select” tool, or by using Ctrl+A.

After all the elements are selected use the “Start 3D viewer” function on the “Advance reinforcement 3D viewer” toolbar.

If the model is not completely reinforced (some structural elements are missing reinforcement), Advance Concrete displays a warning message.

Using the 3D viewer dialog window, select the third option “Export to DWG file with 3D solids“.

If the newly created file is opened in pure AutoCAD®, we will see that the structural elements are made only from simple AutoCAD® lines, while only the reinforcement bars are 3D solids.

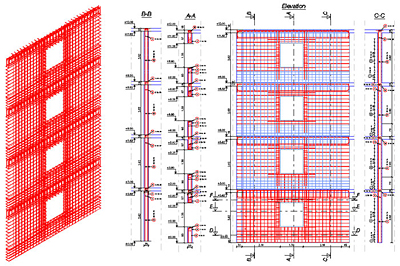

The second step is to convert the structural elements into 3D solids and copy them over the elements from the drawing created using the “3D Viewer” function.

To convert all the structural elements into AutoCAD® solids, select the entities and use the “Convert a structural element into ACIS solid entity” function, on the “Advance Model” toolbar.

This function also provides the option to keep or erase the original structural elements.

After using this option, copy all the ACIS solids by picking a base point. With the help of the base point the AutoCAD® solids will perfectly overlap the reinforcement entities that were obtained in step 1.

Paste the elements in the step 1 drawing by choosing the same base point.

Using the “Quick select” tool select all the AutoCAD® simple lines and delete them.

In the end, a drawing is obtained which contains only AutoCAD® 3D solids. This drawing can be exported as a “dwf” file, and imported in other software like “Autodesk Navisworks“.

The second 2011 DEVELOPMENT AWARD was received by Cosmin BARBU (

The second 2011 DEVELOPMENT AWARD was received by Cosmin BARBU (

March 22nd, 2012.

March 22nd, 2012.