The new stadium in Valenciennes, France, is located near the original one, and has a 25000-person capacity. It is meant to host the Valenciennes Anzin Football Club’s games. ETI Design Office, which has experience in designing several stadiums, is in charge of this project. In addition to the project’s size, the expectations of the Architecture’s Office – with the major constraint of not letting any bolts appear on the steel structure – have called for the use of Advance Steel for easy fabrication and erection at site without errors.

The conception of the new Valenciennes Stadium has required the expertise of ETI Design Office, which managed the complete study of the Alps stadium of Grenoble (France) in 2006 and worked on the extension of Marcel Picot stadium in Nancy in anticipation of the Euro 2016 football cup that will take place in France. The size of the project required four people working full-time on it: one Project Manager, Mr Fabrice Grisot, one Construction Engineer, Mr Stéphane Dottori, and two draftsmen.

About the use of Advance Steel

ETI started using AutoCAD® to draw the first lines of the project in 2D and submit it to the contracting owners. The project owner and architect’s need to view more precise details in 3D about the most complex assemblies required the use of Advance Steel, which has a Building Information Modeling (BIM) approach.

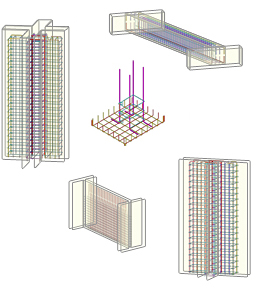

With the flexibility of its numerous tools, Advance Steel enabled fast modeling of all steel structural elements, whether by using integrated libraries of standard sections or by using the automatic conversion tool that allows converting AutoCAD® elements into polygonal plates.

A steel structure without any visible bolts

In order to follow the architect’s wish to have no visible bolts on the structure once the construction is erected, ETI had to design assemblies early from the study phase. Thus, bolted assemblies were designed to ease the transport of parts (that can reach a weight of 10 tons each) and the parts were welded together at site with fastening plates. The welds were then painted and grinded to get a perfect aspect. Therefore, it was necessary to model many weld preparation chamfers on the edges of the plates and the profiles to get a realistic result and, most of all, for these elements to appear clearly on the fabrication drawings.

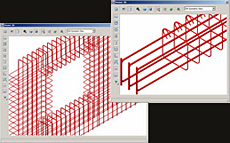

From the 3D model that is automatically numbered, Advance Steel allowed the automatic creation of all fabrication and assembly drawings, with all the necessary labels and dimensions for the workshop. In addition to the drawings generated as DWG files that can be easily read by the architect, the steel parts could be directly transferred as DSTV and DXF files to the CNC machines located in the workshop of a subcontractor in charge of the fabrication of the structure.

Assembling the steel structure without errors

The assembly drawings generated from the 3D model included all the necessary 2D and 3D views for the assembly teams to perfectly understand everything at site. Since all verifications of clash detection were applied on the Advance Steel digital 3D model, no adaptations at site were needed during the erection of the structure.

This slideshow requires JavaScript.

Following an increasing interest from the Turkish market, on 9th of November 2011, starting at 10.30 EEST, a Live Demo for

Following an increasing interest from the Turkish market, on 9th of November 2011, starting at 10.30 EEST, a Live Demo for  ParkerSteel, the largest privately owned steel stockholders in England, employing over 450 people, and one of the major firms bringing employment to the Canterbury area, is promoting

ParkerSteel, the largest privately owned steel stockholders in England, employing over 450 people, and one of the major firms bringing employment to the Canterbury area, is promoting