GRAITEC is pleased to announce that its subsidiary GRAITEC Romania received the status of Gold Independent Software Vendor.

At the beginning of June 2011, the R&D center of the GRAITEC Group, GRAITEC Romania, has renewed its status as a partner for Microsoft, by receiving the Gold Independent Software Vendor competency.

Of the 640,000 organizations included in the Microsoft Partner Network, only 1% of them have a Gold diploma. Therefore, GRAITEC is part of a very short list of partners around the world, who have achieved this high degree of competency.

This certification comes as an addition and also an acknowledgment of the expertise, experience and performance of GRAITEC software solutions, based on recent Microsoft technologies. GRAITEC Advance software solutions passed the compatibility tests for Microsoft Windows 7 since October 2010, obtaining the compliancy logo: “Compatible with Windows 7”.

As a Certified Microsoft Gold Partner, GRAITEC proves once again the exceptional technical skills, and continuing concern to ensure and increase customer satisfaction. Through the collaboration with Microsoft, GRAITEC aims to offer its customers significant benefits to support its business development and provide a genuine competitive advantage.

Ionel DRAGU, GRAITEC R&D Director, comments: “We received the Gold ISV certification because our software pack is fully compatible with the Microsoft platform. This achievement acknowledges once again the quality of our products based on Microsoft technology”

Manuel LIEDOT, GRAITEC Chief Product Officer, comments: “Since the success of any company is provided by its ability to adapt to market requirements, this certification proves that our products and services are capable to keep up with new trends. Our mission is to provide a comprehensive and integrated solution to ensure the best performance in building design and civil engineering.“

During the NASCC 2011 steel conference,

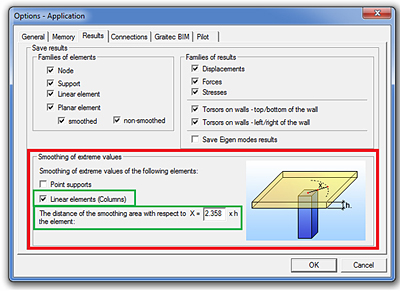

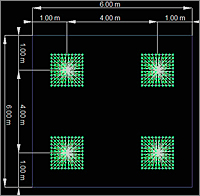

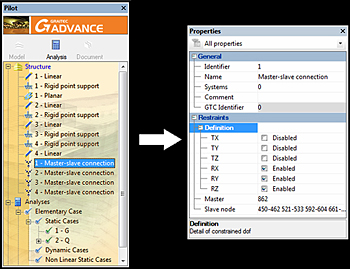

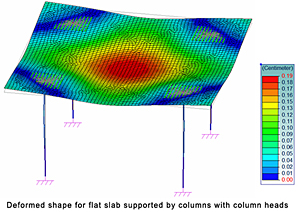

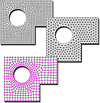

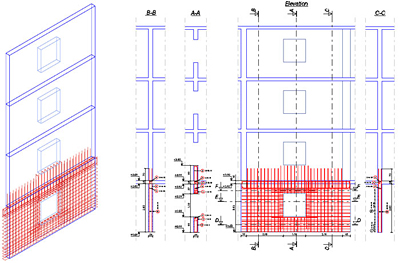

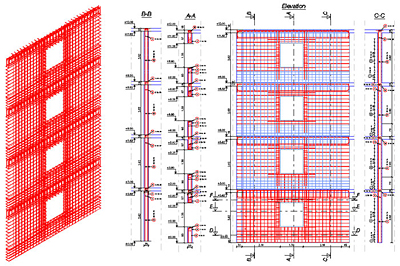

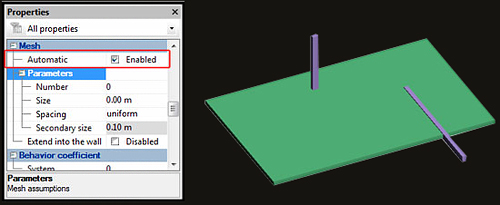

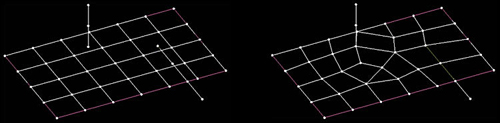

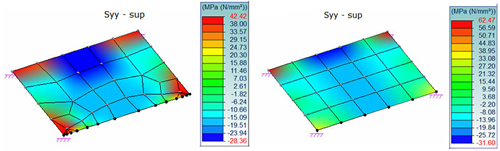

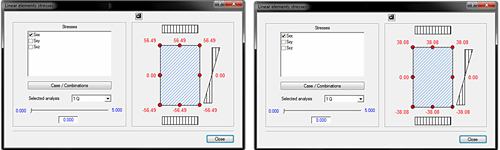

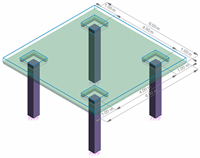

During the NASCC 2011 steel conference,  In the following example we will consider a flat slab made of C20/25 concrete, with a 15 cm thickness, which is supported by four C20/25 concrete columns (40×40 cm). The column head dimensions will be 90×90 cm and the depth of the head is 25 cm. For calculations we will consider the self weight of the elements and a live load of 5 kN/m2. The size of the mesh element is set to 0.1 meters.

In the following example we will consider a flat slab made of C20/25 concrete, with a 15 cm thickness, which is supported by four C20/25 concrete columns (40×40 cm). The column head dimensions will be 90×90 cm and the depth of the head is 25 cm. For calculations we will consider the self weight of the elements and a live load of 5 kN/m2. The size of the mesh element is set to 0.1 meters.