Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

In 1981, LEGRAND chose to diversify its client base and its business activities by creating a Steel Construction Department in the Quincieux site (Dpt 69). This department includes its own design office which is equipped with a modern and recently renewed IT infrastructure.

Currently, LEGRAND employs about 200 people.

Jean-Sébastien COURIVAUD, Design Office manager and Jean-Charles MASBOEUF, Draftsman, report their satisfaction of the Advance Steel software.

How did your drawing software equipment evolve within your Design Office?

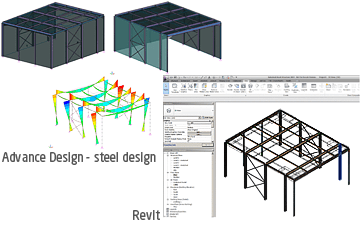

J-S COURIVAUD: Ten years ago, we switched from the drawing board to the use of AutoCAD® in 2D, and then we realized the projects were becoming more and more complex. So we have equipped the Design Office with 3D CAD software dedicated to the steel construction industry in which 30 people are working at the Quincieux site. We initially started with Prosteel before choosing Advance Steel. After a personalized demonstration, it was clear that Advance Steel would provide us with significant productivity savings through the automatic detailing and the quality of the final drawings.

Today, we have 4 Advance Steel licenses to deal with our footbridge and highway bridge projects.

What are the advantages of Advance Steel compared to the software you were previously using?

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated AS document manager, which facilitates the overall project management.

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated AS document manager, which facilitates the overall project management.

J-C MASBOEUF: Our footbridges typically include curved elements such as lower arches supporting the steel structure and the bridge deck. Advance Steel knows how to manage these kinds of elements without affecting the global performances of the software.

How have you customized Advance Steel to match your work methods?

J-S COURIVAUD: Customized drawing styles have been created to produce drawings perfectly corresponding to our presentation criteria (dimension styles, line thickness, dimensions, etc.) and they can be directly launched from a dedicated toolbar that we have also created on our own.

J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments.

J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments.

With the help of the GRAITEC technical support, we configured Advance Steel to work with our fabrication machines at the workshop so that the unfolding of folded plates can be obtained by the criteria of the machines (value of the plate elongation, folding radius, plate thickness, etc.).

Can you give us a description of the footbridge project you recently built with Advance Steel?

J-C COURIVAUD: The construction is a pedestrians/cycles footbridge (access to Anonnay between Peaugres and Davézieux on the RD820). This steel footbridge with 40.30m straight span consists of a mixed steel/wood frame and a concrete floor on HEA 200 beams spaced every 3.40m.

The supporting structure is made up of 2 tapered glue-laminated arches 48cm apart and braced with steel parts. The latter are associated to the level of the deck with 2 lateral steel beams of constant height and connected vertically by two transverse V shaped steel stays (welded plates steel profile stays). The total weight of the structure is 32 tons.

How did you collaborate with the other companies working on this project?

J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

To conclude, what is your general impression of Advance Steel?

J-S COURIVAUD: Advance Steel allowed us to definitively move on to 3D design which gave us new opportunities and solutions to architects complex requirements. Also, the produced documents perfectly match the needs of the workshop and our clients.

J-C MASBOEUF: Once adapted to our needs, Advance Steel has proved to be very easy to use simultaneously allowing us to deal with projects even more and more complex and atypical.

The American Institute of Steel Construction (AISC), headquartered in Chicago, is a not-for-profit technical institute and trade association established in 1921 to serve the structural steel design community and construction industry in the United States. AISC’s mission is to make structural steel the material of choice by being the leader in structural-steel-related technical and market-building activities, including: specification and code development, research, education, technical assistance, quality certification, standardization, and market development.

The American Institute of Steel Construction (AISC), headquartered in Chicago, is a not-for-profit technical institute and trade association established in 1921 to serve the structural steel design community and construction industry in the United States. AISC’s mission is to make structural steel the material of choice by being the leader in structural-steel-related technical and market-building activities, including: specification and code development, research, education, technical assistance, quality certification, standardization, and market development. Australian Steel Institute (ASI) is the peak national body of the steel industry. The ASI works to increase the awareness of the benefits of steel and promote Australian made steel as the material of choice. Increasing the competitiveness of the Australian steel industry and its member companies is central to that vision. Technical advice is available to members. Services include a library and resource centre from which information and advice are available from a wide range of overseas and local publications. The ‘Steel Australia’ magazine is published by the ASI.

Australian Steel Institute (ASI) is the peak national body of the steel industry. The ASI works to increase the awareness of the benefits of steel and promote Australian made steel as the material of choice. Increasing the competitiveness of the Australian steel industry and its member companies is central to that vision. Technical advice is available to members. Services include a library and resource centre from which information and advice are available from a wide range of overseas and local publications. The ‘Steel Australia’ magazine is published by the ASI.

There are different available choices:

There are different available choices:

The project consists of the three buildings which make up the centre – the remodeled Victorian vicarage, the classroom block, made of a steel/concrete hybrid design, with a very complicated roof and the Wessex Auditorium, an assembly hall with a complex box section truss design.

The project consists of the three buildings which make up the centre – the remodeled Victorian vicarage, the classroom block, made of a steel/concrete hybrid design, with a very complicated roof and the Wessex Auditorium, an assembly hall with a complex box section truss design.

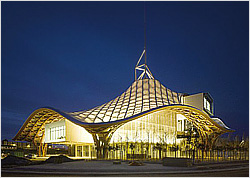

The Centre Pompidou-Metz is a large hexagon structured round a central spire reaching 77 meters high, with three rectangular galleries weaving through the building at different levels. The great nave covers 1,200 m² and provides flexibility for the exhibition of large artworks, with the ceiling rising progressively from a height of 5.70 to 18 meters.

The Centre Pompidou-Metz is a large hexagon structured round a central spire reaching 77 meters high, with three rectangular galleries weaving through the building at different levels. The great nave covers 1,200 m² and provides flexibility for the exhibition of large artworks, with the ceiling rising progressively from a height of 5.70 to 18 meters.