Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

The steel structure of unique design was detailed in ADVANCE Steel by Briton Fabricators Lt. The building process started in November 2011 and over 10,000 components have been put together to compile the structure. It forms an elevated section of the Living Street and will be a gateway feature for Manchester Road. The bridge is close to a surface level signalized crossing which serves a bus stop on the guided bus route. All bridge ramps are 1:20 gradient, and the bridge 3.7 m in width. Access through the public park is 1:15 gradient.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

The fantastic new bridge links up local communities on either side of the bridge, providing a pleasant route for cyclists and pedestrians, and enabling quick and easy access to the town centre and other essential links, which were missing before. It also offers a more gentle approach to the old footbridge, which was nearly 40 years old and in need of serious maintenance to address time related deterioration. Manchester Road Bridge was built approximately in the same position as the old footbridge and was completed in September 2012. Hundreds of people turned out to see the bridge officially being opened. Although, during an average weekday, 621 people use the surface crossing of Manchester Road, and only 340 the footbridge, for reasons of safety the public authorities encourages everybody to use the new bridge to cross this busy junction.

This year, we are delighted to announce that

This year, we are delighted to announce that  Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

Founded in 1956, LEGRAND is involved in the field of railway engineering, metalwork and signage industries throughout France for over 50 years.

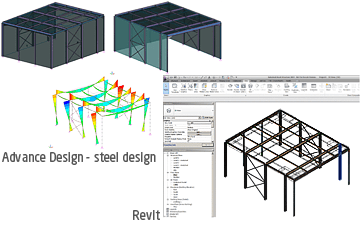

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated

J-S COURIVAUD: The main saving concerns the drawing time creation which is extremely fast with Advance Steel. In addition, a permanent link exists between the 3D model and all the generated documents using the integrated  J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments.

J-C MASBOEUF: We extended the Advance Steel catalogs with steel profiles used for our bridges. We also added new anchors that secure the structure on concrete abutments. J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

J-C MASBOEUF: We exported the entire Advance Steel 3D model to the ACIS format and we sent the electronic file to MATHIS, the company in charge of the wooden railing of the bridge. For their part, they completed the 3D model by precisely positioning the overall handrail and other wood laths between the steel posts in inverted V, which required specific and precise cuts at the ends of the wooden elements. Then, this completed model was sent back to us and I could import all the wooden parts in my Advance Steel model to automatically produce overall drawings representing the steel structure, the concrete bridge abutment and all the wooden elements.

There are different available choices:

There are different available choices: