With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

Ondrej Nepela Winter stadium is the oldest hockey hall in Slovakia. It was first build in 1940 and was recently renovated for the 2011 World Ice Hockey Championship. During the competition its name was temporarily changed to Orange Arena.

According to A. Bezák, the director of the supplier company Ingsteel, 80% of the building had to be demolished for the reconstruction. The new stadium has an increased capacity of 10,055 seats.

The arena is also home to Slovan Bratislava, one of the best hockey clubs in the region (founded in 1921).Matches of Slovan are said to have the best atmosphere in all KHL so if you ever wanted to experience top-tier hockey in Europe, here is probably the best place.

The stadium has three ice surfaces and serves not only as a hockey arena, but also as multi-purpose arena, so from time to time events such as concerts or performances take place in here.

Design office: INGSTEEL Ltd

Location: Bratislava, Slovakia

Software used: Advance Steel

From April- 17th 2013 GRAITEC presented its Structural BIM Solutions “Advance Steel” and “Advance Design” at the NASCC Conferences in St-Louis, USA. The highlight was the presentation of the new 2013 versions of Advance Steel.

The NASCC takes place every year and it is the most important fair for the steel construction industries in the USA and one of the biggest fairs The Americas.

The GRAITEC team is very satisfied with the result. They had interesting discussions with GRAITEC customers and established contact with many new qualified prospects.

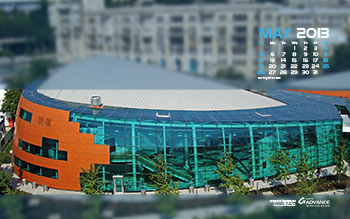

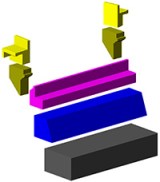

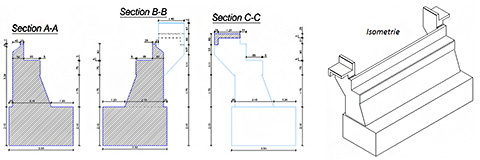

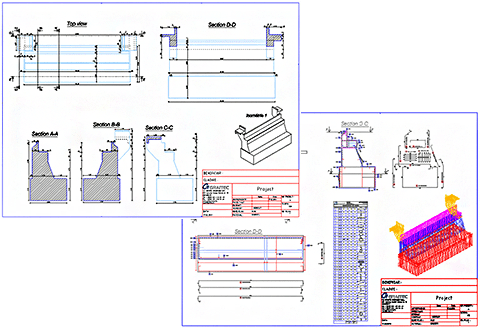

The article describes how we can create reinforcement and formwork drawings for structures with a complex geometry, namely bridge abutment using Advance Concrete. The bridge abutment is a part of infrastructure which is created at the ends of the bridge in order to take the transmitted loads of the bridge superstructure and the supports of the access path to the bridge.

The article describes how we can create reinforcement and formwork drawings for structures with a complex geometry, namely bridge abutment using Advance Concrete. The bridge abutment is a part of infrastructure which is created at the ends of the bridge in order to take the transmitted loads of the bridge superstructure and the supports of the access path to the bridge.

To define the chosen geometry, an ACIS block can be created or the complex geometry can be divided into several blocks having a simple geometry which can be assembled in order to obtain the initial model.

We chose the second method for reasons related to the flexibility of Advance Concrete while modeling volume elements.

How to create any 3D concrete shape

Advance Concrete provides the creation of any 3D and 2D shapes. The predefined concrete shapes can be chosen from the library or new ones can be created. To add a new concrete shape it is enough to create a closed contour and then save the shape in the concrete library. These new shapes can then be used either in the current drawing or for other projects.

The created concrete elements are defined as beam and column structural elements. These are positioned one in regard to the other, composing the entire concrete ensemble.

How to obtain a 3D reinforcement cage for special concrete shapes

The reinforcement drawing is created by selecting all the concrete elements. In the created reinforcement drawing, sections are added through the specific concrete zones.

The definition bars are created in one section and then distributed in elevation or top view. Several types of bars (straight, U and L bars) and distributions (linear, variable, multiple and quantitative) are available for use. The most frequent reinforcement bars are polygonal and straight bars and linear and variable distributions. Concrete covers can be set for each leg of the polygonal bar.

A reinforcement bar distributed in one view will automatically be available in all views, as long as the 3D power option is activated in the reinforcement drawing.

A reinforcement bar distributed in one view will automatically be available in all views, as long as the 3D power option is activated in the reinforcement drawing.

In order to obtain a correct reinforcement cage, the collisions between bars have to be avoided. The bar collisions can be visualized in 2D and 3D representations. They can be easily checked and corrected, at any point.

In order to obtain a correct reinforcement cage, the collisions between bars have to be avoided. The bar collisions can be visualized in 2D and 3D representations. They can be easily checked and corrected, at any point.

The bar detailing and reinforcement symbols can be done both manually (they can be customized and saved in the reinforcement symbol library) and automatically.

The bars numbering and lists creation is automatically done. Sub-entity marks are assigned for variable distributions, emphasizing that the variable distribution belongs to a single shape definition bar.

The drawings are created according to standard STAS 438/1,3 -89. The drawing creation according to other standards is similar.

Formwork details

The formwork drawing is created by adding the desired sections and elevations for structural elements, assigning specific hatches and line weights. The dimensioning of sections is quickly done by adding intersection and level dimensions.

Layout and Print

The reinforcement and formwork drawings can be placed in any page format. Also the views can be grouped and the title block can be attached according to the chosen format.

Numbering of the reinforcement bars and lists can be done in layout mode. The drawings can be printed one by one or by selecting several from the available print window.

Test it yourself

We have shown a simple example of a formwork and reinforcement cage created for a complex shape of the structural element. If you want to see the model described above, please download the specific model and drawings from here or, as a pdf file from here.

The example was created in Advance Concrete 2013.

With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

AEC Mag.com is the online presence of AEC Magazine, UK’s number 1 journal for decision makers in Architecture, Engineering and Construction. AEC Magazine has a bold agenda that reflects the evolutionary nature of this fast-moving sector with its proliferation of software and hardware technologies and the collaborative working practices that are integral to today’s design and engineering workflow.

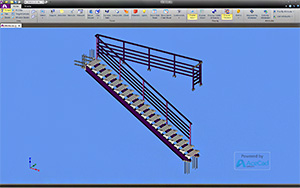

Greg Corke, Managing Editor for AEC Magazine, offers a first look at GRAITECs first release for this year: ADVANCE Steel 2013. For version 2013, the software remains focused on quality and enhanced efficiency: “Having done a major re-write last year, the 2013 release is about improving user productivity. GRAITEC has focused on four main areas — user interface, raw performance, modeling enhancements and drawing issue and re-issue.”

The start page is new, offering users a quick look at recent projects, videos, tutorials, FAQs and others. For the interface however, the biggest change is found in the tool palette, from which many of the model manipulation commands are found. In terms of performance, the graphic engine has been optimized, new viewing modes are available and the general speed has been improved. “GRAITEC has placed a big emphasis on performance and 64-bit support means there are now no limitations on model size, providing the workstation has enough system memory.”

The modeling process has been improved thanks to new intelligent tools made available to users. This reflects directly to the production and quality of the drawings, which are now “less manual”on the way these are updated or referenced.

“While the performance improvements will no doubt be welcomed with open arms, it is the workflow enhancements that will arguably have the biggest impact — particularly when it comes to minimizing the amount of manual re-work required on re-issued drawings”, Greg Corke concluded.

As part of an ongoing project Graitec UK have been working hard to improve the drawing styles in Advance Steel to give better results in more situations. It is a fact that different users desire different things and would draw the same things in different ways. Therefore, some degree of compromise is always required when delivering a set of style for universal use. However, we believe we have now been able to produce a set of styles and related drawing processes that will give clearer drawings in the vast majority of cases meaning far less manual editing is required. Furthermore the process of creating the drawings can be streamlined.

Key Benefits / changes of these styles (in no particular order):-

Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

Manchester Road Bridge in part of the Living Street Project, a lottery-funded project focused on the development of a suitable, convenient and safe route across Manchester Road, which will have the potential to visually enhance this important gateway into the city. This new walkway is a people-orientated, street environment that links up people with places using broad, high-quality, avenue-like routes for pedestrians and cyclists linking up residential areas, schools, shops, health care, parks and town center.

The steel structure of unique design was detailed in ADVANCE Steel by Briton Fabricators Lt. The building process started in November 2011 and over 10,000 components have been put together to compile the structure. It forms an elevated section of the Living Street and will be a gateway feature for Manchester Road. The bridge is close to a surface level signalized crossing which serves a bus stop on the guided bus route. All bridge ramps are 1:20 gradient, and the bridge 3.7 m in width. Access through the public park is 1:15 gradient.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

It is made of over 350 tonnes of steel, 210 meters long in total with two main spans over Manchester Road of 22 meters and 24 meters. It is supported by almost 100 piles buried into the ground carefully engineered to avoid underground services and Bradford Beck. At the central reservation dividing Manchester Road a 17m high rectilinear extension to the column forms a towering central feature which marks the visual centre of the bridge crossing.

The fantastic new bridge links up local communities on either side of the bridge, providing a pleasant route for cyclists and pedestrians, and enabling quick and easy access to the town centre and other essential links, which were missing before. It also offers a more gentle approach to the old footbridge, which was nearly 40 years old and in need of serious maintenance to address time related deterioration. Manchester Road Bridge was built approximately in the same position as the old footbridge and was completed in September 2012. Hundreds of people turned out to see the bridge officially being opened. Although, during an average weekday, 621 people use the surface crossing of Manchester Road, and only 340 the footbridge, for reasons of safety the public authorities encourages everybody to use the new bridge to cross this busy junction.

With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

CAD Digest, one of the most popular online sources for CAD, CAM & CAE articles and testimonials, reviews ADVANCE Steel, not as a design tool, but as a solution for accelerating the design process. James Finkel, author of the review (with experience in mechanical engineering, programming, custom design engineering, QA and software testing) explains why ADVANCE Steel is a powerful tool for all types of projects.

ADVANCE Steel introduces three versions of the software, depending on the scope and versatility of the project: Standard, which is a “light version”, limited to 10 tons of steel, Professional, which has no limits to the weight of the steel and can be tested for free as a 30-day Trial Version (this being the version used by James Finkel for his review), and Premium, which also includes the multi-user technology. Each of the available packages has been created to meet users’ business needs, depending on key software selection criteria: ease-of-use, interoperability, drawing output and, of course, cost.

For this review to be as accurate as possible, the author requested the assistance of Benoit Lalonde, a GRAITEC technician from our offices in Canada, in creating a model with a large variety of joints: beam-beam, beam-column, column with four beams of unequal sizes, plate work, column-to-concrete footers, and beam-to-wall connections. The creation of the model was the first step in determining the capability and efficiency of the software in handling unusual or complex requests.

Concerning input and output of data, ADVANCE Steel 2012 offers many solutions – use built-in CAD tools or import the model from AutoCAD or Revit and, as a result, generate reports in plain text, Word documents, XML, Excel spreadsheets, and so on, and issue a full suite of the projects’ drawings.

Throughout the modeling process, users are provided with an extensive library of smart objects, libraries of customizable automatic joints (more than 300 joints), customizable drawings, and generation of all detail drawings required by fabrication shops. ADVANCE Steel provides all the necessary tools to create, save and reuse simple or complex custom connections. “This flexible software handles a wide range of steel design situations”, states the author.

Regarding operability and features, James Finkel tested the customization of joints, the stress at joints, generation of reports and defining new and more complex shapes. His conclusion was that ADVANCE Steel 2012 offers a full-featured structural steel design system, with a wide range of output formats, according to customer needs. “Starting from an AutoCAD model, Revit, or working within the CAD supplied within the software, users have a wide array of tools for joint construction with point and click for individual or multiple joints. The software has an equally wide array of output formats and features”, James Finkel declares.

Following our mutual longstanding development work with GRAITEC, AceCad Software is delighted to announce a new model link to the GRAITEC platform.

This new model link connection enables the round tripping of information from GRAITEC products into BIM Review and StruM.I.S with feedback into the GRAITEC authoring product. Thus a true circle of information can be completed to the benefit of all in the construction supply chain and facilitates true Building Information Modeling (BIM).

This alliance will allow greater flexibility with our mutual clients for data sharing, facilitating amongst many other exciting possibilities – Entity Face Clash Detection and 4D Planning and Progress Feedback with StruM.I.S. Furthermore, this development will offer an easy and adaptable multiple data sharing system enabling significant time savings through labour and error minimization.

Alexandre Tartas, GRAITEC Group COO commented: “We are very pleased with our recent development venture with AceCad as it provides improved flexibility to our reciprocal clients in data sharing and the multi model merging process; it will save users valuable time handling and managing key operational data through multiple fabrications solutions. This partnership will enhance our products functionality and will strengthen our position in the dynamic and ever changing AEC market providing increased competitive advantages.”

Technical Director for AceCad Software, Mr Simon Inman, commented: “This great achievement is once again a result of our longstanding partnership with GRAITEC. This exciting collaboration will reinforce our continued outstanding relationship and it will prove to be beneficial to our mutual clients in delivering exceptional business efficiencies.”

About AceCad Software

Established in 1986 AceCad Software Ltd, a member of the international RDS Group is a leading supplier of advanced software solutions to the international construction industry, delivering sustainable and advanced competitive advantages to our valued international clients. AceCad develops a range of software for BIM collaboration, design to construction project management and dedicated steel work fabrication. AceCad products have consistently transformed its customers’ business in the construction supply chain. With core business areas in the AEC Building and Construction and Industrial, Process and Plant sectors, AceCad has international operations in ten countries and provides software to customers around the world.

With calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

Every year GRAITEC creates an annual wall calendar. For each month a project designed with GRAITEC Advance software is presented.

This year is no exception! There were a lot of great projects to choose from, but unfortunately we had to pick only 12, the rest you will be able to see on our reference page, on our blog or Facebook page.

If you wish for your project, designed with a GRAITEC software solution, to appear on next year’s calendar, or for others to find out about your great projects through our media pages, do not hesitate to contact us.

The following are the projects presented in this year wall calendar:

With Calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

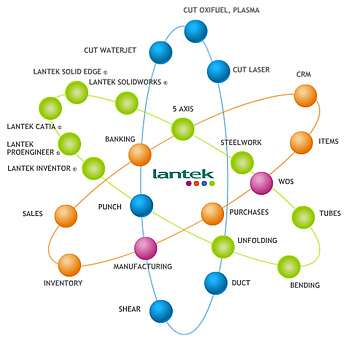

Lantek, a world leader in sheet metal and structural steel manufacturing solutions, and GRAITEC, specialists in BIM (Building Information Modelling) are collaborating to integrate their software solutions to provide a seamless design and manufacturing solution for the structural steel industry. Furthermore, the partnership will allow both companies to expand and consolidate their businesses in new markets.

Lantek develops and markets world class CAD/CAM/MES/ERP software solutions for the sheet metal and structural steel industry and, with the announcement of the signing of a collaborative agreement with GRAITEC, aims to develop its extended technical innovation programme. The alliance will enable both companies to offer clients a single, integrated and technologically advanced system. The partnership signifies the start of a professional relationship for the two companies, enabling them to consolidate their position in the sheet metal and steel construction industry at an international level.

GRAITEC is a pioneer in the development and marketing of software dedicated to structural design and engineering for the construction industry.

It has more than 25 years of experience in this market, 12 branch offices dotted around Europe, North America and Asia-Pacific, a team of 260 employees and more than 40,000 users worldwide.

With a turnover of more than 25 million Euros in 2011, GRAITEC is currently the only supplier able to offer a complete and integrated range of design and structural analysis solutions for the steel, concrete and wood construction industries.

GRAITEC offers innovative BIM technology, which increases productivity and safety through automation, integrated design and process control. Its software has the capacity to intelligently exchange data, making collaboration between professionals in construction design and those in the construction sector simpler and more flexible by facilitating sound, intelligent and fluid communication.

As part of the collaborative agreement, the two companies are working on a bi-directional integration process between the GRAITEC Advance BIM software and the Lantek Steelworks solution. This will bring together both technologies, by sharing the models designed in GRAITEC Advance Steel. As a result, a structural steel project will be able to be managed in Lantek Steelworks and its progress fed back into Advance Steel, providing users with a flexible and simple management process. The benefit is a more powerful and rapid solution, which makes it possible to dynamically generate and manage structural project information, substantially reducing the time and resources spent on design and construction.

As part of the collaboration the two companies will coordinate the innovation process and reserve the necessary technical and human resources to achieve their goals in such a way as not to affect their normal product development schedules. As part of this process, Lantek has implemented a training programme for its technical team in GRAITEC’s products to speed up and effectively manage the integration.

“Lantek intends to integrate with all structural design software applications on the market,” says Alberto Martínez, CEO at Lantek. “This initiative enables Lantek, once again, to manifest its desire to develop integral, dynamic and ultra-efficient solutions which are at the forefront of technology and adapted to the needs of users, enabling them to increase their competitive edge“.

“GRAITEC, just like Lantek, is an innovative and flexible company which focuses on globalisation and technical collaboration in order to enrich its solutions, particularly within the framework of structural construction,” says Alexandre Tartas, managing director at GRAITEC.

“We are very pleased about this initiative, as it means working with a company renowned in the industry. It allows us to enhance our Advance Steel solution from a functional and technical point of view, and gives us the means to respond efficiently to the challenges which face companies and structural engineers.“

In addition, the partnership between the two companies will give them both the opportunity to tap into new fast-emerging markets and increase their presence in other countries such as the United Arab Emirates and Asia for GRAITEC, and Canada and Romania, Eastern Europe for Lantek.

GRAITEC reports a turnover of 21.27 million Euros for the first three quarters of 2012. GRAITEC turnover increased 22% compared to the same period in 2011, exclusively due to organic growth. The profitability has also soared by more than 6-fold compared to the same period in 2011. The main reason for this performance is due to a massive adoption of the solutions developed and sold by GRAITEC.

Highlighted performances:

Advance Steel, the Structural BIM solution for the steel industry, has grown year to date by +54% in revenue and over 45% in number of seats. Advance Design, the Structural BIM analysis and design solution, has achieved a remarkable +20% growth in turnover. Advance suite, the complete international Structural BIM suite of Graitec, reports a year to year growth of +35%.

Mentioning only some of the Geographical best performers:

• North America has done an amazing job in the steel construction industry, increasing the Advance Steel turnover by +121%.

• GRAITEC Asia/Pacific, over performed with a +86% growth.

• GRAITEC Russia, in the same range of performance, increased its revenue by +73%.

• Europe has also delivered some great performances, in all countries where Graitec operates, a few highlights are:

Alexandre Tartas, COO of GRAITEC, comments: “We are very proud to report another solid performance at the end of Q3 2012. Graitec not only grows but does it in a very profitable business model, which is a very remarkable performance. It is difficult to talk about every unique performance, when every subsidiary, every sales office over performs. Graitec continues to reinforce its Structural BIM Specialist position in the market, providing and implementing best-in-class solutions to contribute to the daily challenges of our customers. Of course Q3 is only a stage in 2012 and everyone is actively working on maintaining this level of performance until the end of the year. This year to date 2012 accelerated growth gives Graitec high ambitions and expectations for Q4 and we can expect to over achieve the initial targets in turnover, operating margin and profit.”

With Calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200

GRAITEC is pleased to announce the opening of a new office and dedicated training suite in Burton-Upon-Trent, Staffordshire, UK. The additional office will complement GRAITEC’s existing headquarters in the South of England, offering the latest in design and analysis software for the construction industry.

The construction industry is a highly competitive sector and it is obvious that businesses in the UK are not just looking to survive but thrive. GRAITEC UK is committed to delivering cutting-edge technology designed to help improve its customer’s productivity and efficiency.

Making our technology and quality services more accessible, to more businesses, gives them the confidence and support they need to invest in our technology and get ahead of the game.

Carl Spalding, UK Managing Director comments: “This is a very exciting time for GRAITEC UK and our expansion is as a result of our continued growth both in the UK and globally. In addition to the incumbent strength of our Analysis and Design technology, SuperSTRESS, our best seller is our 3D BIM software for steel engineering and detailing, Advance Steel. It is through the demand and success of our Advance Steel software that has enabled us to expand at such a rapid pace and our new office, strategically located in Staffordshire, will provide easy access from all the major road networks and airports.”

Graitec UK is extremely pleased to welcome James Flatt to the team as the Regional Sales Manager heading up the Midlands office. James began his career in the construction industry working as a draughtsman for a large steelwork fabricator. In recent years he has worked for several major software companies supplying 3D modeling and BIM solutions to the market. James’s knowledge and experience will be valuable asset to both GRAITEC and its customers.

James Flatt adds: “I’m absolutely delighted to have joined GRAITEC at such an exciting time for the company. Seeing growth of +45% in 2011 compared to the previous year speaks volumes in terms of the direction in which we are going. The new standalone version of Advance Steel is receiving very good reviews and should be considered a viable option for steelwork fabricators and detailers alike.”

To help support and further develop the fast rate of growth we are experiencing in the UK market, GRAITEC UK has also contracted theconsultancy services of Wayne Rawson through his company – Wayne Rawson Consulting Ltd. Wayne has been in the steelwork industry for over 30 years and has worked at senior level with several large industry-specific software providers. His knowledge of the steelwork industry and steel detailing software solutions in particular is proving a great addition to Graitec team. He has already been instrumental in helping numerous companies with advice and business planning through to software deployment when they are considering an upgrade of their existing CAD software to Advance Steel as their preferred steel detailing software solution.

“Having worked with suppliers of steel detailing solutions over a good number of years, I understand both the capabilities available within the CAD products in the market and what detailers really need from a steel detailing solution. Advance Steel is an excellent 3D multi-material modelling system that offers a very serious alternative for companies using older software systems that are looking for a highly competent and flexible software solution with increased capabilities, backed by a very successful organization growing at an incredible rate“

Formally Integer Software Ltd (est. 1984), Graitec UK boasts an integrated range of structural design and analysis software used by 90% of the top 100 UK engineering consultancies and offers a wide range of quality services from professional training to custom software development to ensure customers get the best from us and our software. Importantly its support service is rated extremely highly by its customers and it is imperative that the company ensures this level of service is maintained from our Midlands office. The appointment of James combined with Wayne’s experience and the full backup and support of its established technical team will ensure its quality services are continued.

With Calendar

Size: 1280×1024; 1600×900; 1680×1050; 1920×1200

Without calendar

Size: 1280 x 1024; 1600 x 900; 1680 x 1050; 1920 x 1200